Lightweight and designed materials

To fulfil this requirement, Arkema supports the automotive sector, but also the aeronautics industry, by developing high performance thermoplastics as substitutes to glass or metal.

The objective: to reduce the weight of structures and therefore help minimize their fuel consumption and CO2 emissions.

Arkema focuses its innovation efforts on products that contribute to "Combat climate change and its impacts", one of the 17 UN's sustainable development goals (ODD 13).

Thermoplastic composites: an alternative to thermoset composites

The benefits of composite materials

50% lighter than steel, 30% lighter than aluminum and remarkably strong, composites have many applications in the nautical and transport industries.

Composite materials consist of three elements:

- a reinforcement charge: an armature, generally made of carbon fiber or glass fiber, which concentrates most of the mechanical properties of the finished part.

- a matrix: a resin binder that permeates the reinforcement and solidifies.

- optional additives: they improve the properties of the resin.

The matrix may be a thermosetting resin - also called thermoset - (epoxy and polyester in the main) or a thermoplastic resin.

Recyclability: the real asset of thermoplastic composites

Thermoset composites have the characteristic of hardening permanently thanks to a crosslinking mechanism; as a result, they cannot be transformed again or recycled. Thermoplastic composites provide real answers to remedy these limitations, as they are:

thermoformable and heat-weldable: the thermoplastic material softens when the composite parts are heated. These can then be shaped or welded (a process easy to control, avoiding the use of adhesives).

recyclable: it is possible to recover and reuse the material by melting it.

Because of all these benefits, Arkema's R & D is particularly interested in the development of thermoplastic resins for composite parts.

Arkema, a pioneer in ultra high performance thermoplastic materials

Rilsan® HT polyamide: resistance to high temperatures

To be able to use thermoplastics in an extreme heat environment, Arkema has developed Rilsan® HT.

This biosourced polyphthalamide (PPA) polyamide is flexible and can replace metal or rubber in several under-the-hood flexible pipe applications thanks to its resistance to high temperatures.

An automotive part made of Rilsan® HT resin is up to six times lighter than a metal part.

Kepstan® PEKK: Durability and sturdiness

To replace metal in cutting-edge sectors such as civil and military aeronautics, Arkema has developed the Kepstan® PEKK product range (polyether ketone ketone).

This polymer of the extreme, while also lighter, features the same properties as metal in terms of abrasion and impact resistance as well as non-combustibility:

- 40% lighter than aluminium

- withstands more than 260°C

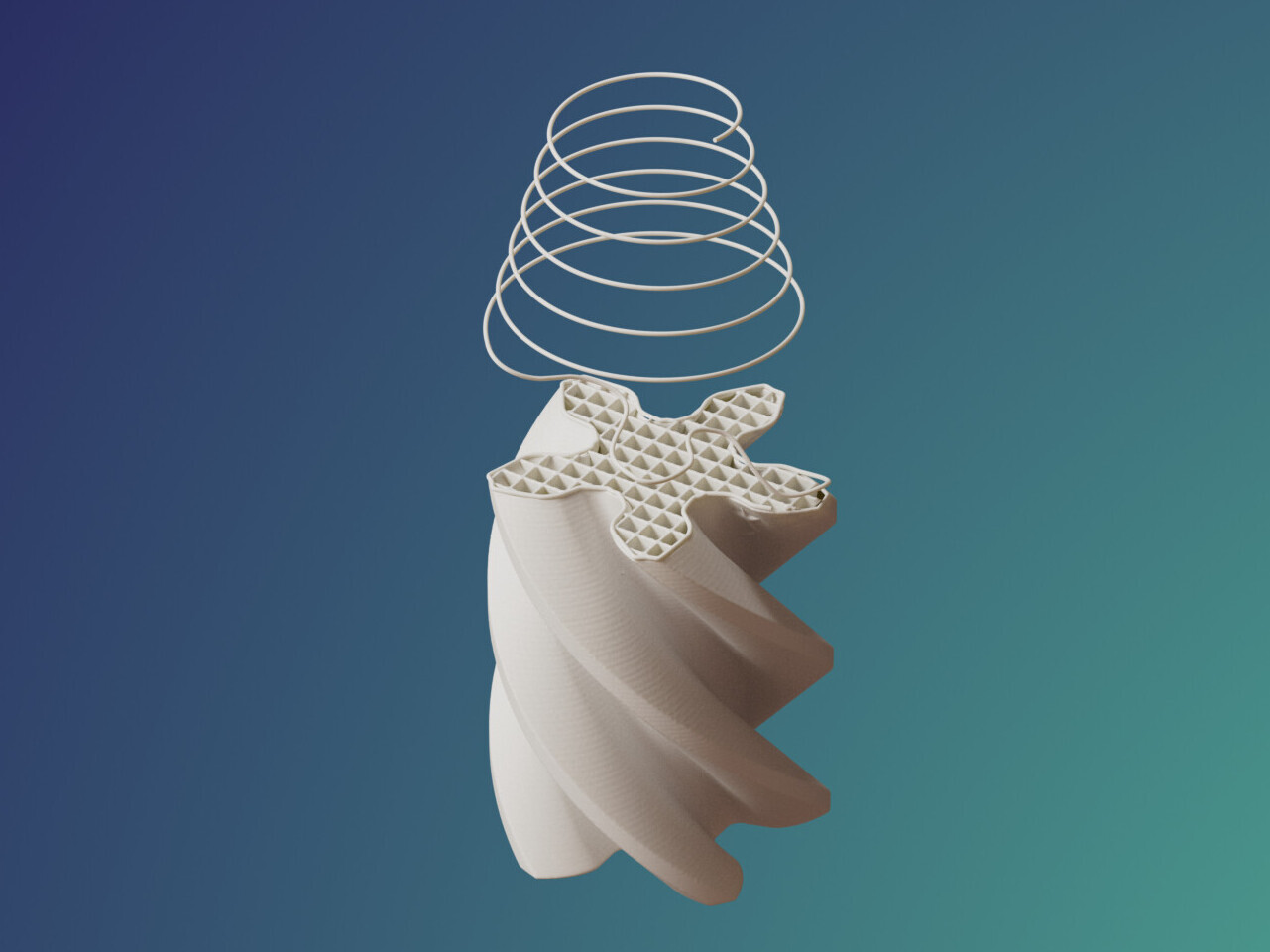

Elium® resin: resilience of a composite, recyclability of a thermoplastic

To meet the challenge of thermoset composites that cannot be remelted or recycled, Arkema's R & D recently developed Elium®, the only liquid thermoplastic resin on the market that can be processed in the same way as liquid thermoset resins with the same manufacturing processes: the parts obtained have mechanical properties identical to those of thermoset parts, with the added benefit of being thermoformable, heat-weldable and fully recyclable.

Car interior, body and body parts, hoods, sailboat hulls and floats, and even wind turbine blades: this new resin will revolutionize the composite industry in the coming years.

A carmaker's dream is the same as a chemist's who would like to replace glass or metal with recyclable plastic. When you reduce a car's weight by 100 kg, you save about 0.4 liter of fuel for every 100 kilometers, or 5%, which is huge."

3D printing: Arkema's expertise

Revolutionizing the methods of production

3D printing offers total freedom of design for complex parts and eliminates the need for molds, which are often time consuming and expensive to develop.

The resulting flexibility and time-saving also mean significant financial savings for design offices and industrial companies when it comes to producing prototypes and limited runs. 3D printing technology could totally revolutionize our methods of production and our consumer habits.

Read: Thinking beyond printing: the full value of additive manufacturing

Our centers of excellence

Converting new applications to 3D printing requires close collaboration with machine manufacturers, software editors or end users. Arkema engages in this sort of collaboration and brings the best of its advanced materials and innovative chemistry to optimize part properties and surface finishes, or higher throughput.Centers of Excellence are collaborative spaces for chemists, material engineers and printing experts to work together.