3D printing materials

A market leading product portfolio

Easy 3D free on-demand 3D printing service platform

- Get an automated material recommentation for your project

- Request instant quotes from 3D printing part manufacturers

- Order your part and get it delivered

A better use of material properties

We provide support to choose the right material and the right printing technology based on your applications. We offer high-performance materials for 3D printing for highly demanding applications.

Check our materials for chemical resistance, transparency, impact resistance, dielectric properties, heat resistance or energy return applications.

Chemical resistance - Kepstan® PEKK

In this video, we tested the reaction of Kepstan® PEKK and PEI to MEK. After 8 hours of exposure to MEK, we observe how PEI printed piece has changed in color, while PEKK remains the same.High-Performance Materials for FFF 3D printed Kepstan® PEKK withstands aggressive chemicals and suits extreme applications.

High Toughness and Impact resistance - N3xtDimension® liquid resin

UV/LED liquid resins are the top choice if you are looking to achieve tough, transparent and highly detailed parts.Impact resistance - Rilsan® PA11

In this video, we tested SLS printed Rilsan® PA11 with PA12 for impact resistance.Using the vertically installed tube and falling steel ball test, we can see that the PA12 piece has broken while PA11 withstand the impact with the steel ball and the piece remains intact. SLS printed Rilsan® PA11 shows superior impact resistance event -30 °C low temperatures.

Dielectric resin - N3xtDimension® liquid resin

Our N3xtDimension® UV/LED liquid resins with dielectric properties are the material of choice for radio frequency technology applications.Ductility – Rilsan® PA11

In this video, we compared 3D-printed pieces of PA11 and PA12 for ductility. After repetitive manipulations like folding and unfolding, we see how the PA11 piece remains tough and flexible without breaking.Use Rilsan ® PA11 powder when you need ductility, rigidity and strength for your 3D printing application.

Heat resistance - N3xtDimension® liquid resin

N3xtDimension® heat resistant UV/LED curing resins can resist up to 150°C without compromising on mechanical properties.Energy return – Pebax® TPE

Pebax® TPE is an energetic elastomer that is perfect for applications requiring lightweight, flexibility and energy return.High energy return means a high percentage of the energy put into flexing the polymer (i.e. the step of an athlete) is returned during rebound. Compared to TPU polymers, Pebax® elastomers exhibit much lower energy loss, even at very low temperatures.

Brochure: 3D printing unlocking the next revolution

- How does additive manufacturing contribute to sustainability?

- A leading portfolio of innovative solutions for each of the major 3D printing technologies

- Liquid resins for energy curing

- Thermoplastic powders for bed fusion

- Thermoplastic pellets for filaments extrusion

Case study - 3D printing

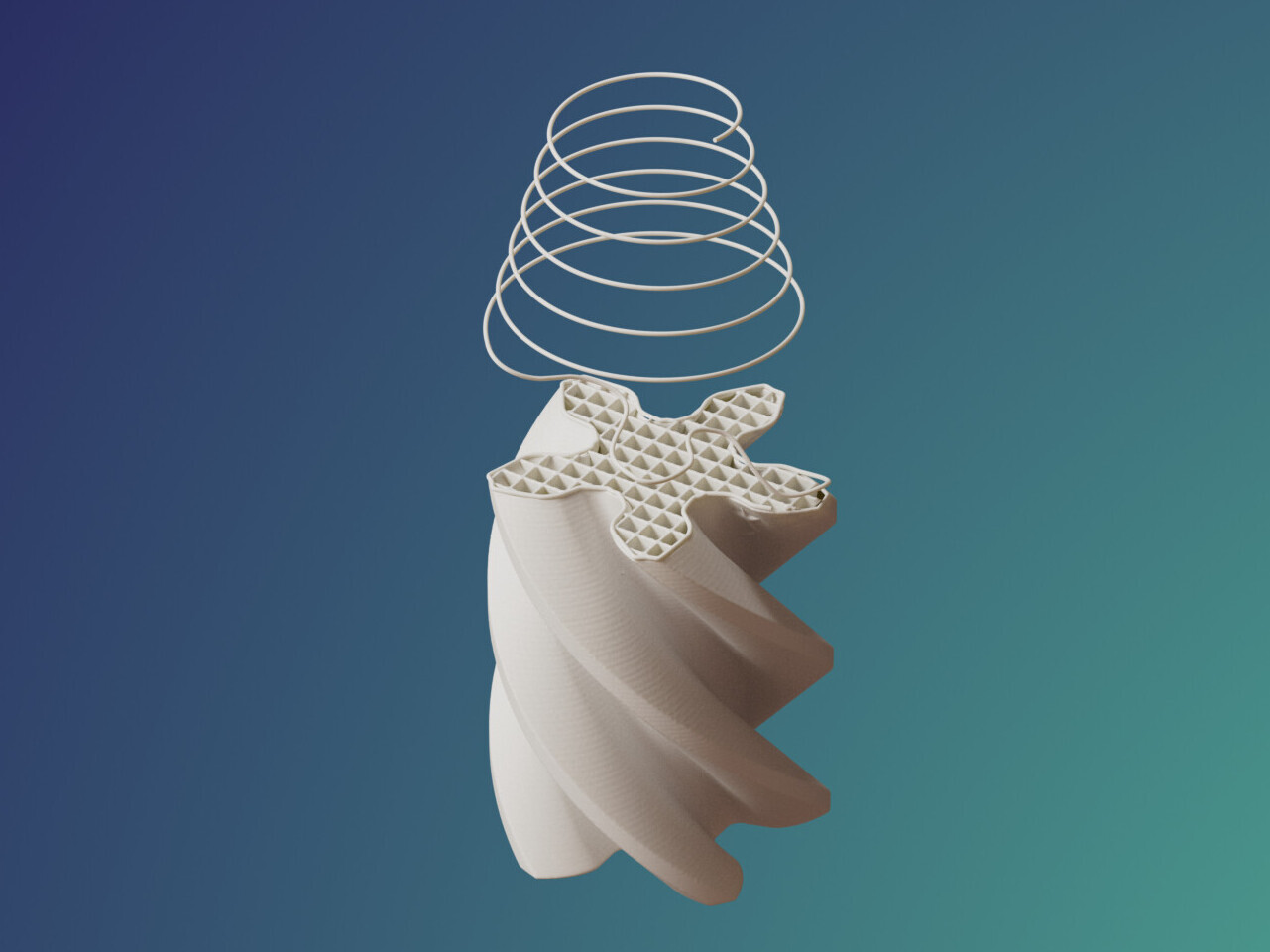

3D printed and tailor-made: orthopedic insoles made with advanced bio-circular polyamide 11

Our experts are ready to assist you

Our experts are ready to assist you

Our specific offering for other industries:

- Agriculture & food industry

- Chemical & plastic industry

- Cooling & refrigeration

- Health, hygiene & beauty

- Mining & metallurgy

- Packaging

- Pulp & paper

- Water management

- Automotive, transportation & aerospace

- Coatings & inks

- Building & construction

- Renewable energy & energy storage

- Adhesives & sealants

- Electrical & electronics

- Oil & gas

- Composites

- Sport & leisure

- 3D printing

Go further:

3D printed and tailor-made: orthopedic insoles made with advanced bio-circular polyamide 11

Orthopedic insoles are highly customized devices fabricated by podiatrists for each ...

Read more

Mar 17, 2022

Semi-crystalline Kepstan® PEKK Seals via Fused Filament Fabrication on the miniFactory Ultra®

Apr 8, 2021