Battery Solutions

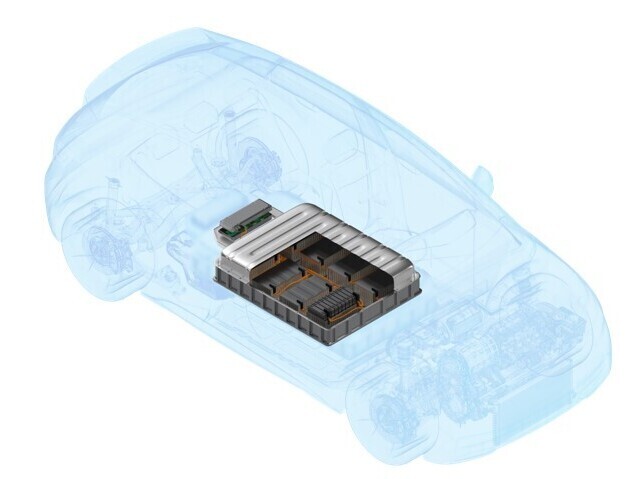

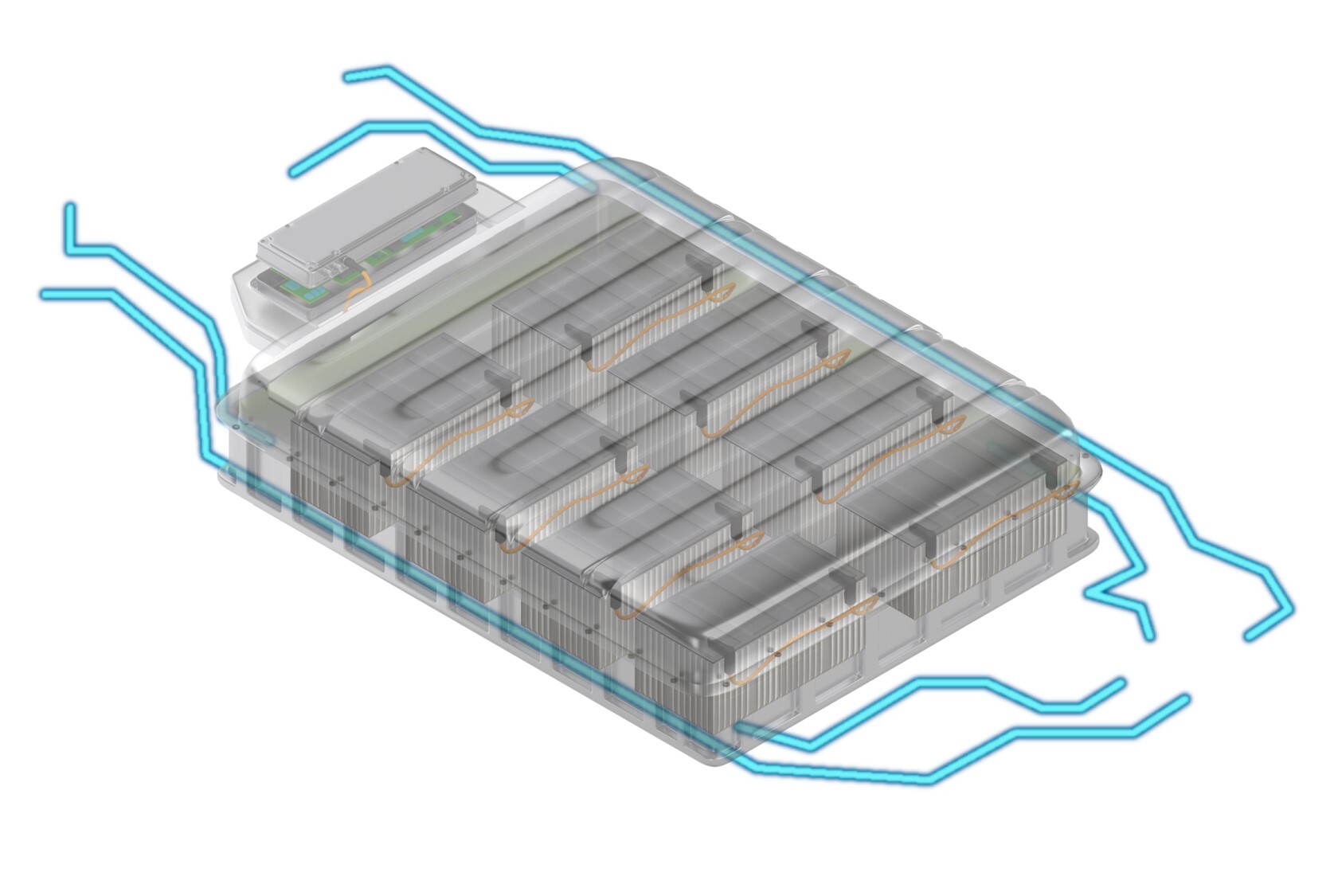

Despite the impressive progress made in lithium ion energy storage, the challenges faced by battery systems remain significant in terms of energy densities, cost optimization, improved safety performance and durable life cycle. Our goal is to develop cutting-edge solutions for next generation vehicles. Our solutions help to optimize performance and improve the battery energy density, duration, weight reduction and recharging time. Our market-leading portfolio of battery solutions cover applications inside and outside the cell, from cell to module and battery pack assembly up to battery system integration into the vehicle.

Inside and outside the cell, we have the market leading technology portfolio of specialty materials for battery systems that increase efficiency, safety and reliability

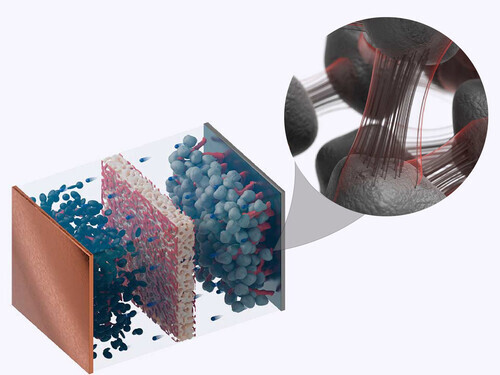

Inside the cell

Our solutions help to optimize the chemical reactions inside the cell to boost the battery performance in terms of charging time, prolonged lifecycle and high energy density.

IncellionTM El acrylic based solution for anode

Key challenges for the battery industry are to increase the energy density while relying on easy to handle technology to allow large scale adoption. Incellion™ El solutions brings to the battery manufacturer new materials that will help them to better apprehend these challenges.

Comprehensive range of polymers for separator coating

The separator is a crucial component of a battery, serving as an electrically insulated membrane that sits between the anode and cathode. During the charging process, it facilitates the exchange of lithium ions from the anode to the cathode, and vice versa during discharging.

To enhance the overall performance and safety of the battery, specialized coatings can be applied to both sides of the separator. However, the process of selecting the appropriate coating can be challenging due to multiple factors such as separator system, technology, and battery end-user application.

At Arkema, we offer a comprehensive range of polymers that enable a wide selection of tailored solutions for separator coatings. We continue working enriching our portfolio to offer our customers more freedom of choice in terms of separator coating function and performance. Our team of separator coating experts is dedicated to supporting your battery project and finding the best compatible solution for your coating targeted performance. We work closely with you to identify the right solution for your end application, ensuring optimal performance and security.

Kynar® PVDF

Kynar® Flex grade is specifically designed for separator coating application, improves the cell manufacturing process, reduces the cell deformation, and improves the cycling performance. Kynar® PVDF resins have become the reference for use in lithium-ion cells for its dimensional stability that helps to improve the battery safety. Available in fine powders or latexes, Kynar® Flex are in used in Water based System or Solvent ones, as ceramic binder or adhesive coating.

DISCOVER ALL KYNAR® PVDF GRADES ADAPTED TO YOUR NEEDS HERE

IncellionTM Sp acrylic solution

Incellion™ Sp are acrylic based binders for battery separators to enhance the mechanical, thermal, and chemical stability, ensuring overall battery safety and performance. Their role in maintaining the structural integrity and consistent performance of the separator makes them essential for the reliable operation of lithium-ion batteries.

Discover our range

Electrolyte salts

Electrolytes ensure the flow of lithium ions within the battery, which is directly linked to battery lifecycle. To guarantee long-term performance, electrolytes can be improved using Foranext® electrolyte salts.

LiFSI has the highest ionic conductivity among all lithium salts. Its remarkable electrochemical (>5V) and thermal stability make it an ideal choice to be used as a main salt or additive.

LiTDI is an additive that helps to increase battery life, due to several properties:

- Solid Electrolyte Interface (SEI) stabilization

- HF and water scavenging

- Aluminum current collector passivation.

We can provide expert support for electrolyte solutions for lithium battery development and we are ready to discuss your projects.

Solutions for Cathode

Kynar® PVDF

Electrode binder material is paramount to producing high performance lithium-ion batteries. The Kynar® PVDF grades provide high adhesion to aluminum foil and electrode cohesion, electrode flexibility, controlled swelling, in electrolyte and electrochemical stability.

MORE DETAILS ON KYNAR® PVDF PERFORMANCE FOR ELECTRODE BINDER

Multi-walled CNT as conductive additive

Graphistrength® multi-wall carbon nanotubes (MWCNT) are a highlight of Arkema’s development in nanomaterial technology and are the conductive additive of choice for high-performance electrodes. Indeed, electrical conductivity is key in the development of high energy density and efficient charge or discharge of the lithium ion batteries. Graphistrength® containing composite electrode materials- achieve better electromechanical performance by providing an efficient electrically conductive network in battery electrodes.

Graphistrength® MWCNT is the cutting-edge solution to improve the lifecycle of next generation electric vehicles. Graphistrength® MWCNT is versatile and adaptable to different needs such as lithium cell geometry as well as the manufacturing rocess of the electrodes. Our team helps customize MWCNT in dispersions based on different solvents for different specification requirements.

Incellion™ Pr acrylic based primer on aluminum for cathode

Primers are a layer deposited between the electroactive material and the current collector to provide adhesive and conductive connection. Incellion™ Pr solution helps to design high performance primers.

Discover our range

IncellionTM Rh acrylic rheology solution

Stable slurries contribute to a better deposit of the materials on the different battery substrates like current collectors and separators, providing higher performance, hassle free production conditions and cost reduction.

Incellion™ Rh solutions are electrochemically stable additives designed to perform adequately with the binder materials to provide optimized dispersions of the active materials. With a proven global expertise in rheology management, ARKEMA can support battery manufacturers to design slurry profiles that will give them enhance performance to control the quality of their coating process.

Discover our range

White paper - Immersion Cooling

Liquid immersion as a cooling solution is a promising method to drive mainstream adoption of Electric Vehicles (EV’s).

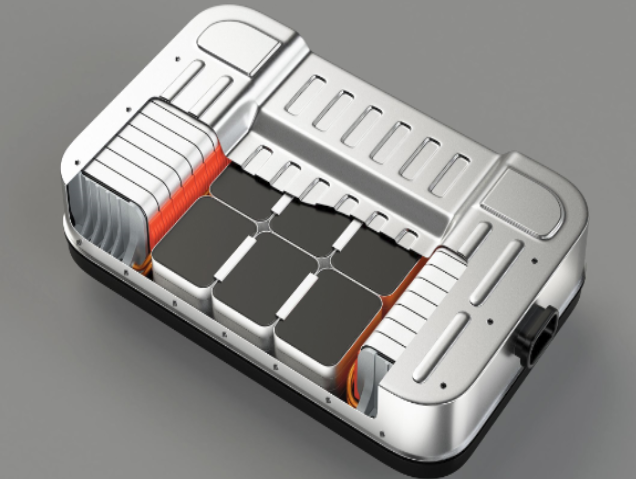

From protecting the cell to module assembly

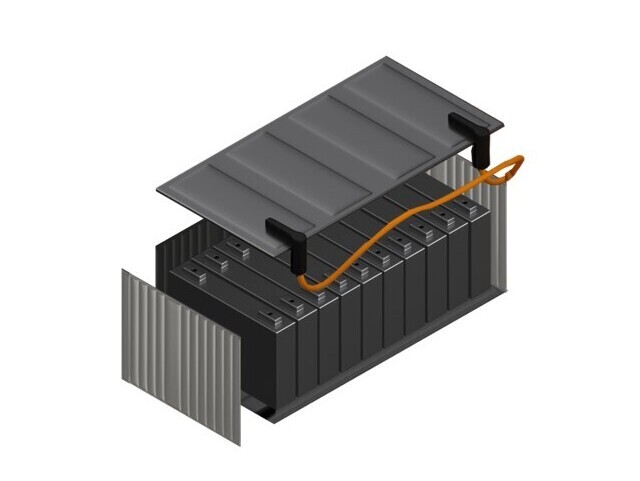

The module is a component of the Hybrid Electric Vehicles (HEV) and Battery Electric Vehicles (BEV) that holds together a group of battery cells.

Once manufactured, the cells need protection to ensure an optimal functioning over a long life span. Making the choice of UV coating not only enables an easier and faster process, but also ensures a coherent protection of the cell without delamination.

Module assembly plays a key role in protecting the cells from shock and vibration that occurs during vehicle operation.

Battery module architecture is crucial for battery system thermal management; therefore, it can incorporate heating, cooling or heat exchange systems.

UV-curable dielectric coatings

UV-curing is a solvent-free, high speed and ambient curing process, allowing instant drying under the UV lamp. It is one of the most sustainable and energy efficient coating technologies, thus making it a smart choice for the protection of battery cells. Indeed, through this technology, the coating of the battery cell can be done at the very end of the manufacturing line.

Sartomer® UV-curable acrylate resins and photoinitiators answer the need for high breakdown strength and volume resistivity, ensuring optimal dielectric performance for electrical insulation of the cells. Our solutions will not cause the film delamination in use observed today with tapes.

Learn more on our Dielectric coatings solutions

By leveraging Group synergies with Bostik adhesive solutions and expertise, Arkema is identifying opportunity to develop coatings with unrivaled adhesion properties between the coated battery cells. Sartomer® high performance oligomers will provide you with best-in-class mechanical properties for the intercell adhesive system, as well as a high adhesion to metal.

Smart adhesives

Bostik smart adhesives provide a large portfolio of solutions covering bonding, cell-to-cell and cell-to module assembly and encapsulation. Whether pouch, prismatic or cylindrical, we cover all cell type assemblies for modules to provide mechanical integrity between the cells and ensure their safety and reliability as well as thermal management. Our solutions are designed to protect battery cells and modules from moisture intrusion, various chemical fluid leaks and exposure to the outside environment.

- Easy-to-process and solvent free sprayable adhesive solutions (pressure sensitive and waterborne adhesives) for pouch cell-assembly

Tailor-made 2K polyurethane adhesive materials for prismatic cells module assembly

Best-in-class MMA based adhesives predestined for cylindrical module bonding with an optimal balance of key properties

Hot melt polyamide adhesives for encapsulation applications, bolstered by our leading position in specialty hot melt adhesives

Thermal conductive adhesives if, in addition, heat transfer and thermal management is required

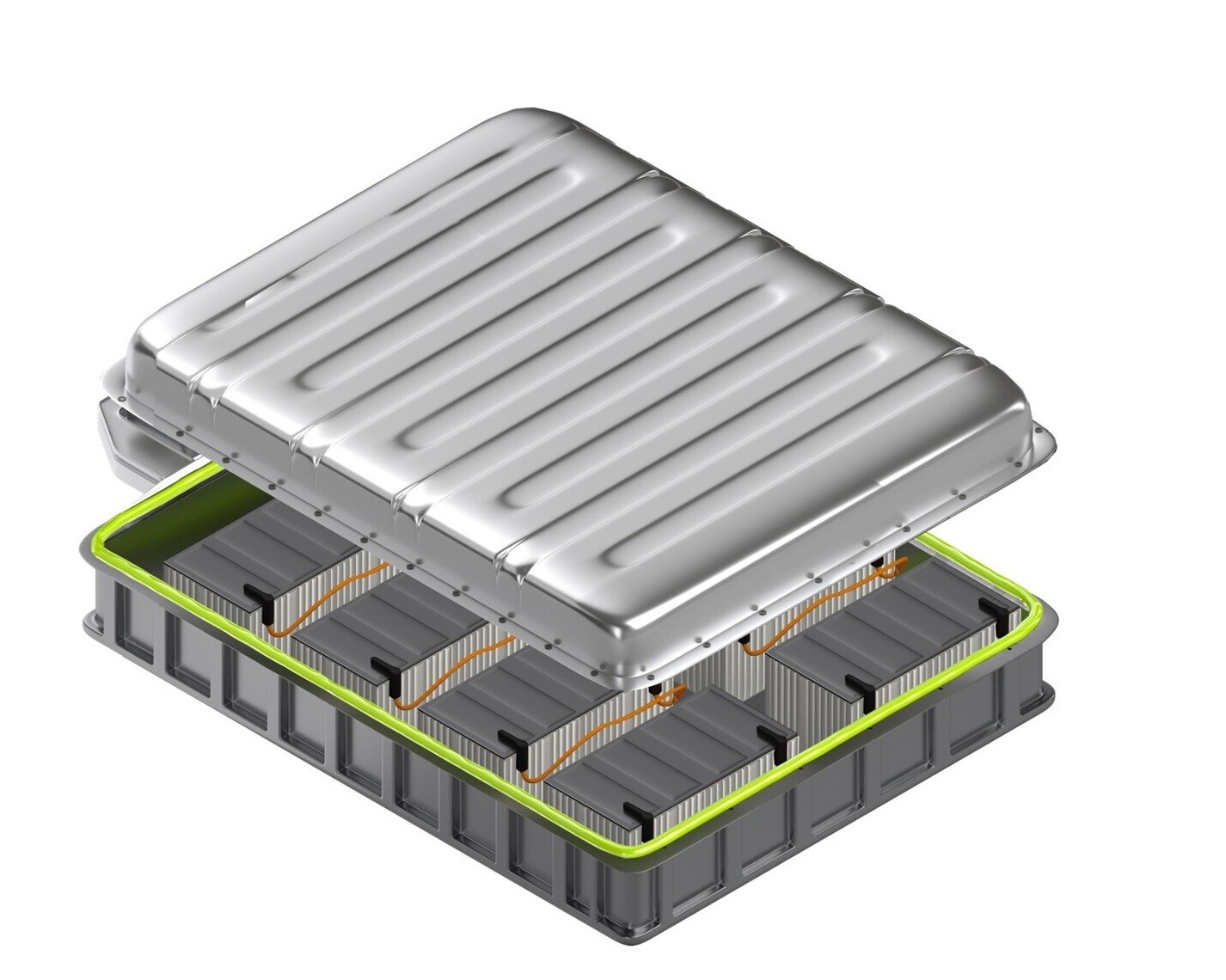

Battery pack sealing and enclosure

Smart sealants

Sealants play a crucial role in battery pack enclosures to protect the battery from exposure to elements that might affect its performance.

Bostik smart sealants are lightweight solutions that help to reduce the weight of battery systems which are often heavy and take up space on the vehicle floor. Bostik smart sealants are ideal for battery pack assembly and are tailor-made to address the needs for removability and adaptability to high-speed manufacturing processes for automotive OEM's. To assemble the pack, adhesion to different substrates is key because the battery pack is made from various metals or composite materials. Our comprehensive portfolio of sealants combined with our expertise in the automotive industry provide the right solution for our clients.

Our battery pack sealants and adhesives contribute to improved battery system lifespan by providing protection thanks to:

- Extreme flexibility

- Excellent durability

- Excellent sealing performance and air tightness

- Serviceability or removability for post repair

- Excellent adhesion with limited surface treatment

- Rapid and precise application enabling high speed automated manufacturing.

Our battery pack sealants and adhesive solutions portfolio contains:

- Battery pack sealing and gasketing: SMP (Silyl Modified Polymers), Butyl, HMPSA (hot melt pressure sensitive adhesives), Synthetic rubber, CIPG/UVFG

- Structural bonding battery pack: MMA (methyl methacrylate), Instant adhesive (2K Cyanoacrylates), 2K-PU (polyurethane).

Thermoplastic composites

The battery pack and enclosure are subject to extreme environmental conditions such as vibrations and shocks that can eventually affect the battery lifespan. Battery pack application materials require superior mechanical properties and high durability to protect the battery’s function. Often in vehicle energy storage systems, the non-energy storing components take up a large space and add to the overall weight. Therefore, advanced thermoplastic composites are key for lightweight structural storages development in next generation BEV and HEV vehicles.

Elium® is the first thermoplastic resin designed for manufacturing composite parts with high performing mechanical properties. Elium® is a game changing resin that helps solve the challenges that the automotive industry faces:

- Lightweight: 30% to 50% lighter than identical parts made out of steel

- Mechanical properties: while being lighter than metal provides the same level of resistance

- Recyclability: possibility to recycle via de-polymerization.

Encapsulating case coating

EV batteries are subject to possible damage from external bodies, such as stone chipping due to their location on the bottom of the vehicle, near the rear wheel. Material requirements for encapsulating cases include mechanical resistance, corrosion resistance as well as insulation properties in order to ensure battery lifespan longevity.

Our Rilsan® Fine Powder high performance solutions are the material of choice for battery metal case coatings. Rilsan® Fine Powders are bio-based thermoplastics made from castor plants suited for extreme condition applications requiring high resistance and durability. Their key properties specific to coating applications are excellent resistance to damage (such as stone chipping), excellent corrosion resistance, high insulation properties and low coating thickness (<200 µm).

Battery management systems

Battery management systems (BMS) are an electronic systems built with the battery pack.

BMS monitor the state of the battery for various performances such as voltage, temperature, charge status and safety. We offer cutting-edge solutions to address the most critical challenges to help improve battery management systems.

From piezoelectric polymers for sensors and high performance thermoplastic coatings to hot melt polyamides for encapsulation and low-pressure molding applications, renewable and bio-based Oleris® advanced material and a fluorinated booster for thermal management, our offer for battery management systems is designed to enable effective power distribution and improved battery lifetime.

Battery immersion cooling system

Liquid immersion cooling is an extremely promising technology for the thermal management of batteries. The battery cells are completely immersed in a dielectric fluid, providing better thermal performance than the current thermal management solutions. In addition, immersion cooling could enhance the safety of the battery. Arkema provides advanced materials that help to improving the immersion cooling.Oleris® advanced bio-materials in the synthesis of dielectric fluids with improved properties

Oleris® n-heptanoic acid, renewable and carbon-neutral C7 fatty acid from Castor Oil, is used as a bio-based building block in the synthesis of high-performance polyol esters (POE), valorized as synthetic dielectric fluids. Oleris® n-heptanoic acid provides to the resulting dielectric fluids an extremely low kinematic viscosity, a lower pour point, an excellent oxidation stability and they are readily biodegradable.

Booster for dielectric fluids

There are many dielectric fluids that can be selected from for use in immersion cooling. Options range from dielectric oils to pure fluorinated fluids. Recent developments are showing that some non-fluorinated dielectric oils can achieve even better performance with the addition of a fluorinated booster. This booster enhances the dielectric properties of the oil, which provides a positive impact throughout the entire system.Fluorinated boosters combined with a dielectric oil help reduce the viscosity and suppress the existing flashpoint of the dielectric oil. The booster has excellent miscibility with most dielectric oils and can enhance the thermal performance of the system.

Battery busbar coating

BEV and HEV applications require highly resistant material to guarantee sustainable and durable vehicle operation. One key component of the battery system is the busbar. Busbars combine a system of electrical conductors, which collect and distributes electrics current to power vehicle subsystems. This power distribution component consists of copper or aluminum conductors and an insulated coating for high-temperature applications.

Our bio-based Rilsan® PA11 coatings meet all the requirements needed for the extreme performance challenges of busbar applications. Rilsan® PA11 coatings provide exceptional abrasion resistance as well as thermal and chemical resistance.

Encapsulation & Low Pressure Molding of electronic components

Electronic components such as sensors and critical connector interfaces require durable and waterproof solutions with suitable mechanical and thermal properties, which address flammability concerns as well.

Our Thermelt™ Hot Melt Polyamides and Born2Bond™ engineering adhesives such as UV Cyanoacrylates are perfectly adapted for encapsulation and protection of these critical components. In the Low Pressure Molding (LPM) applications, our moldable hot melt polyamides offer a durable and bio-based solution, with increased production efficiency and unmatched opportunities for material design. For conformal coating applications, our low-odor, low-blooming and dual curing cyanoacrylate adhesives offer rapid bonding through transparent parts as well as effective cure between opaque substrates.

Piezoelectric polymers for sensors

Lithium ion batteries are prone to gradual capacity fade due to electrochemical processes such as active material dissolution, electrode particle cracking or electrode adhesion degradation. Battery state of health (SOH) is a critical measurement for the reliable and durable operation of lithium ion batteries.

We developed a revolutionary piezoelectric polymer for efficient battery cell monitoring through non-invasive acoustic and ultrasound measurement. P(VDF-TrFE) piezoelectric copolymers, Piezotech® FC, are very sensitive to acoustic waves and ultrasounds. Due to their sensibility, when integrated into a battery, data can be collected to help improve battery lifetime and management.

With our global R&D and technical support, we strive to provide you with the right solution for the protection of critical electronic components:

-

Hot melt polyamide for encapsulation and low pressure molding (LPM) applications bolstered by our leading position in specialty hot melt adhesives

-

Encapsulation: hot melt polyamides, engineering adhesives, UV acrylics

- Encapsulation for electronic components (sensors, connectors)

- Encapsulation and protection of critical connector interfaces.

Lithium-Ion battery recycling

Lithium Ion battery recycling is a fast growing market because it is key that most of LiB components – including precious metals like lithium, nickel, cobalt and manganese - could be reused, in line with current commitments in sustainability and environment protection. LiB recycling processes currently operated are based on either pyrometallurgy, hydrometallurgy or mechanical treatment.

Hydrometallurgical recycling

Hydrometallurgical recycling is considered as the most suitable technology in terms of environmental point of view and it has clear advantages in terms of low energy consumption, high metal recovery rate and high product purity. In the wet hydrometallurgy process, Albone® hydrogen peroxide (H2O2) is the most popular chemical reacting with cathode materials. It acts as a reducing agent in the leaching process, in combination with acids, mainly sulphuric acid. Using hydrogen peroxide in the leaching process allows optimized leaching efficiency and reduced reaction time. Moreover, Albone® hydrogen peroxide has unique environmentally friendly features since decomposition by-products are water and oxygen only. We are committed in producing hydrogen peroxide using world-class technologies, ensuring constant and reliable quality. Based on an efficient supply chain and optimized logistics solutions, Arkema also provides technical support to its customers, including expertise about safe storage and handling, allowing to benefit from Arkema hydrogen peroxide significant advantages.