3D printing: Arkema's expertise

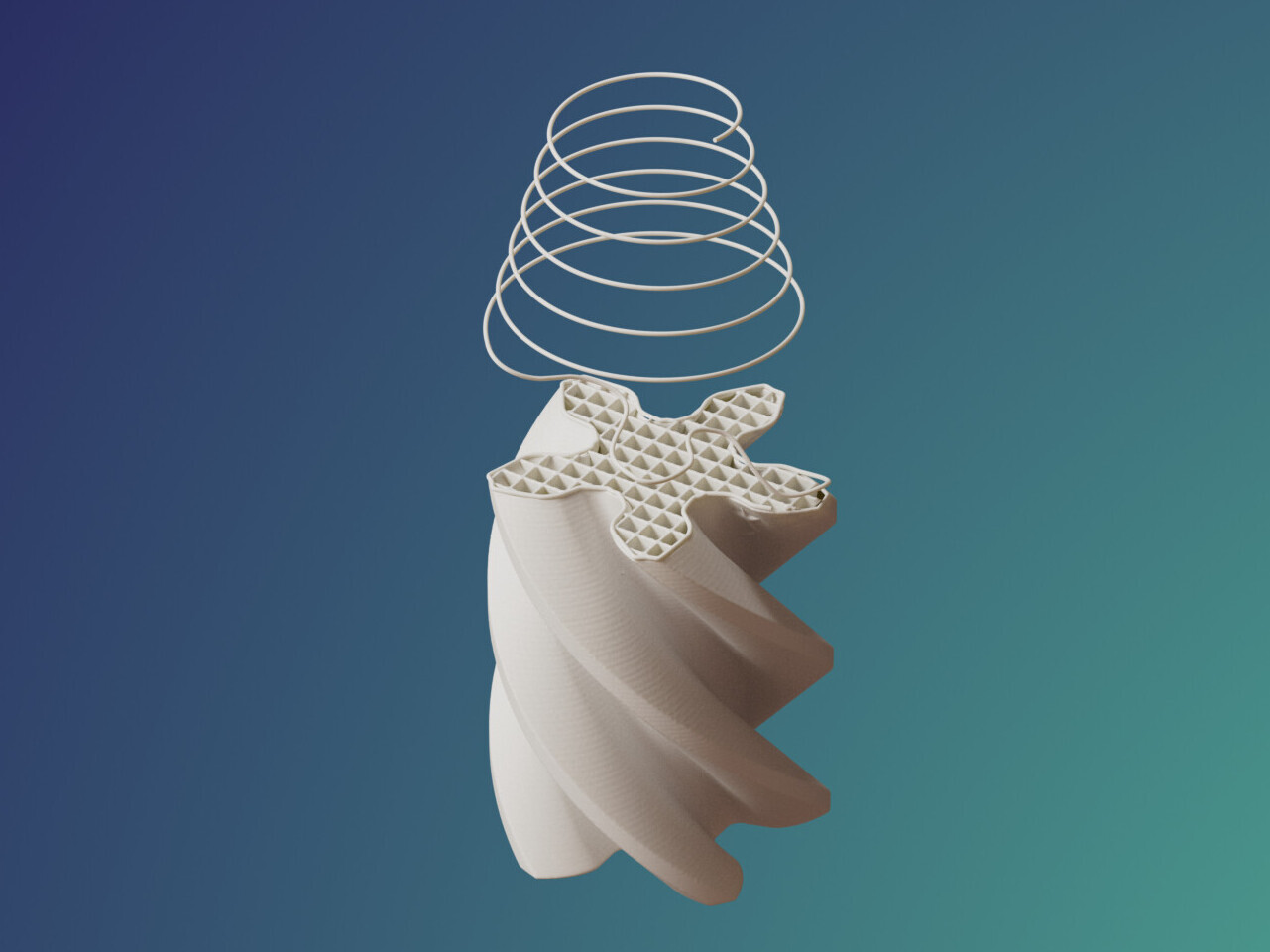

3D printing offers total freedom of design for complex parts and eliminates the need for molds, which are often time consuming and expensive to develop.

The resulting flexibility and time-saving also mean significant financial savings for design offices and industrial companies when it comes to producing prototypes and limited runs. 3D printing technology could totally revolutionize our methods of production and our consumer habits.

Read: Thinking beyond printing: the full value of additive manufacturing

Arkema continues expanding its portfolio of high-performance 3D printing materials and new application developments with sustainability always in mind. Our offering of 3D UV resins, powders and filaments including bio-based grades is also available on EASY3D on demand, the 3D printing service platform developed by Arkema."

A market leading product portfolio

Our centers of excellence

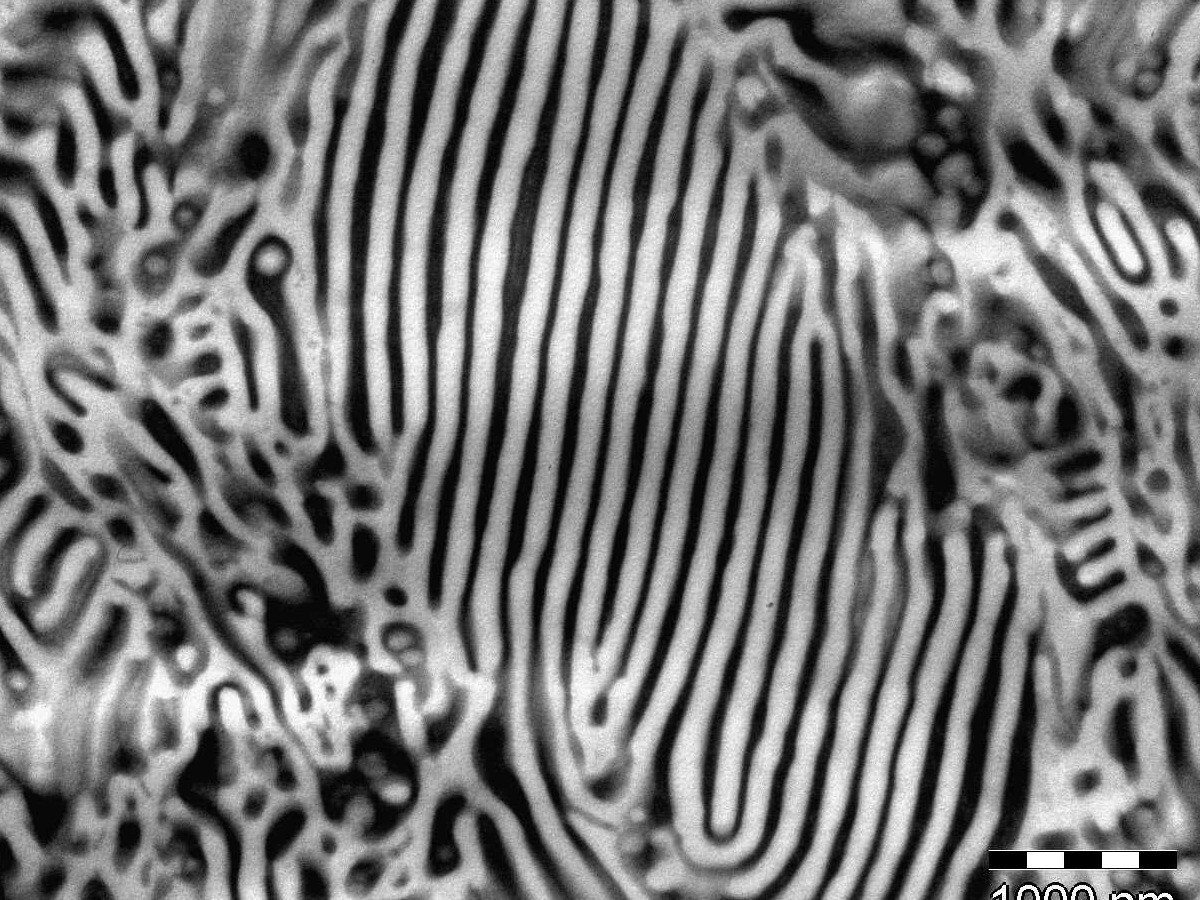

Converting new applications to 3D printing requires close collaboration with machine manufacturers, software editors or end users. Arkema engages in this sort of collaboration and brings the best of its advanced materials and innovative chemistry to optimize part properties and surface finishes, or higher throughput.Centers of Excellence are collaborative spaces for chemists, material engineers and printing experts to work together.