Innovative Materials, Arkema's R&D strategy

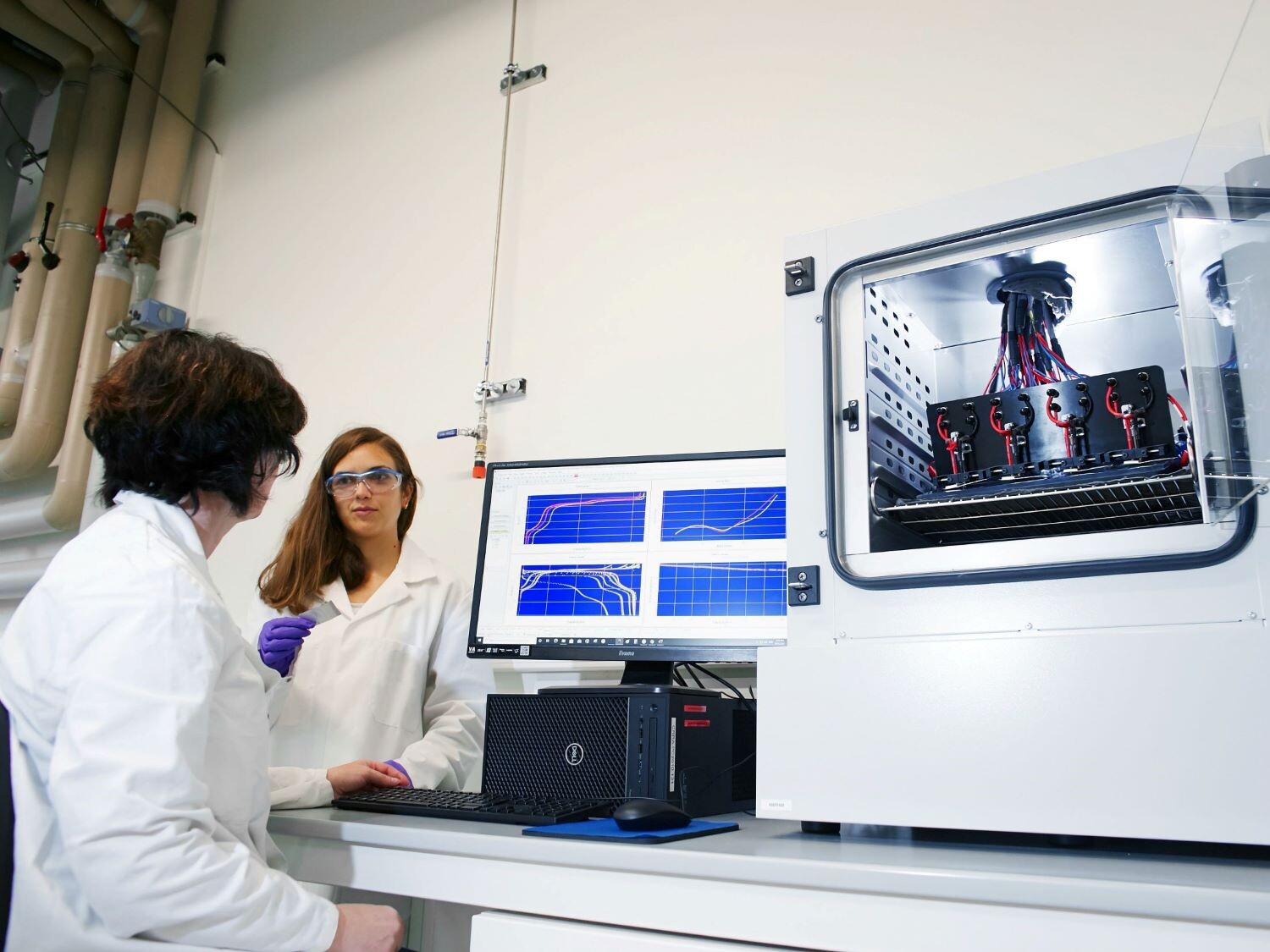

The R&D teams boast experts who carefully watch market trends, and relentlessly work at putting in place pioneering and sustainable solutions.

Arkema group R&D key figures

Go further

The incubator: enhancing high-potential innovations

The role of the "incubator" is to identify products with a high potential and bring them to fruition. Within this original structure with its own technical and financial resources, researchers and scientific directors are charged with developing nanomaterials and new generation polymers.

Graphistrength® carbone nanotubes, Piezotech® electroactive fluoropolymers, or thermoplastic resin Elium® are amongst the innovations which prepare the future of the Group, and are poised to completely transform many application sectors.

INNOVATIVE WITH, our magazine “that connects the ideas of the future”

INNOVATIVE WITH is our magazine that sheds light on our unique R&D expertise in innovative materials and on our collaborations with the greatest experts - laboratories, SMEs, start-ups - in promising areas like new technologies and renewable energies.