Carelflex®, an on-site sulfiding service for refineries

In addition to supplying and delivering the most efficient and highest purity sulfiding agent, DMDS Evolution® E2 (Dimethyl disulfide), Arkema offers Carelflex®, an on-site sulfiding service carried out by highly qualified technicians, providing the technical and safety knowledge, digital monitoring as well as assistance you need for efficient, hassle-free catalyst sulfiding.

- Worldwide

Carelflex®, your premier solution for a flexible and safe sulfiding operation

Professional advice in preparing catalyst sulfiding operation

30 years of expertise

Arkema's extensive experience with over 6,000 insitu catalyst sulfiding jobs completed worldwide, is your asset as you prepare to sulfide your catalyst. Our technical specialists will propose an optimized logistic scheme and help you select convenient implementation, and review the risk analysis and activation procedure, including the amount of DMDS Evolution® E2 needed and its flow rate range.

Delivery of the sulfiding agent

Once a desired delivery date is selected, Arkema allocates the requested high quality DMDS and establishes the most suitable logistics to meet your sulfiding schedule. We can also recommend a container or containers most suitable to your situation: road tankers, semi-bulk and bulk containers (such as ISO containers) are all available. During the last few weeks leading to activation, an Arkema representative keeps in close contact with the refinery to adjust the final delivery date to any unexpected change of the unit turnaround schedule.

Optimize your sulfidings, maximize your runtime

Process equipment changes, new operators, catalyst selection and loading may each have an impact on the safety and efficiency of your unit start-up. Training and procedure review are important preparation steps for your catalyst activation. Arkema provides training in the fundamentals of catalyst sulfiding. We teach the DMDS (Dimethyl Disulfide) chemistry, the sulfiding stages, and pathways to generate H2S via the “efficient sulfur” concept. Our expert help in procedure review and training, utilizes Arkema’s position as a global leader in organosulfur chemistry and our vast experience with catalyst sulfiding.

On-Site technical service

Carelflex® service provides the assistance of a specialized Arkema sulfiding technical expert for hook-up and controlled delivery of the sulfiding product. This ensures accurate and controlled sulfiding under safe conditions. The refiner benefits from Arkema's vast experience with sulfur chemicals and maintains complete control of the operation. The result is maximum catalyst activity and extended run times.

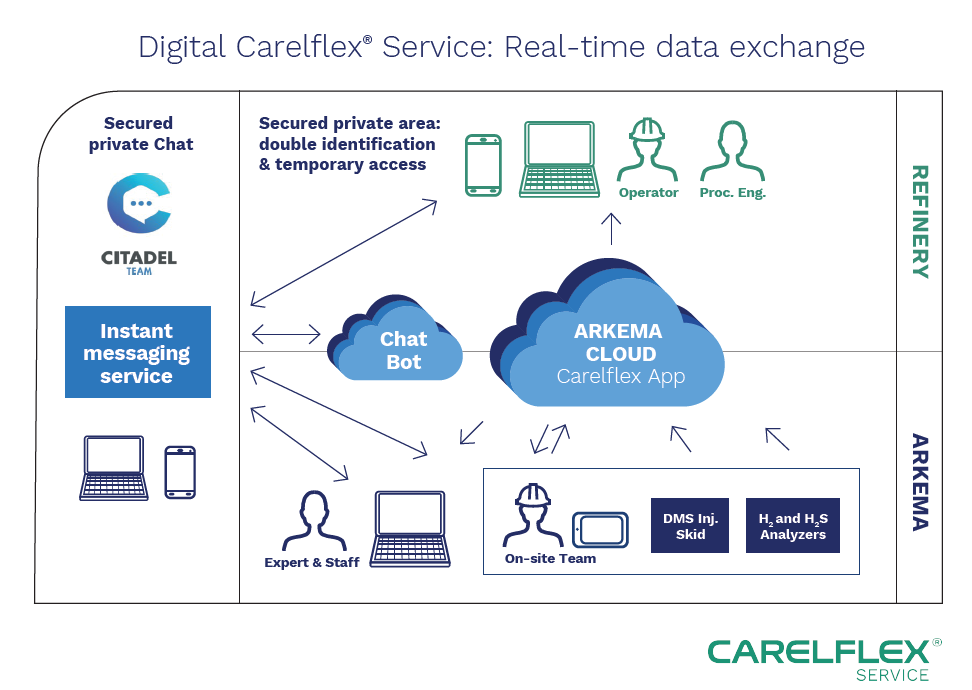

Track data in real time and optimize your sulfiding procedure with Carelflex® Connect:

Carelflex® Connect offers online and real time data reading for a close sulfiding monitoring process: In-line and real time hydrogen purity and hydrogen sulfide analyzers to carefully monitor the sulfiding process and anticipate procedure adjustments, saving time and product without compromising with the operation control. A secured live chat is also available for a fast and easy communication with the Carelflex® team.

Hydroprocessing catalysts sulphiding with DMDS: Carelflex® Connect brings more than IIoT:

READ THE ARTICLE

Service innovation

Thanks to our customer’s confidence and market recognition for Carelflex® top-quality service, Arkema has extended its service portfolio to other applications or other chemical injections:

1. DMDS (Dimethyl Disulfide) injection for Hydrogenation of Vegetal Oils (HVO) plants based on the same catalysts as those used in refineries, these biorefineries produce renewable diesel or jet fuels. Very similar DMDS supply and injection service is required for their hydrotreating catalyst sulfidings.

2. Amine injection for hydrocrackers (HDK) units: during the DMDS activation of the hydrocracker catalyst, the catalyst vendor may recommended an amine injection to temporary deactivate the acid sites of the HDK catalyst, and avoid large exotherms in the catalytic reactor. Arkema manufactures specialty amines and has developed Carelflex® injection services for:

- TBA (Tri-n-ButylAmine, RN-CAS 102-82-9)

- DEAPA (DiEthylAminoPropylAmine, RN-CAS 104-78-9)

- DMAPAP (DiMethyldipropylenetriamine, RN-CAS 10563-29-8)

- TMPDA (TetraMethylPropylenDiAmine, RN-CAS 110-95-2)

Sulfiding Frequently Ask Questions (FAQ)

Why should operators/engineers review the unit start-up procedure when starting up with fresh catalyst?

The unit’s start up procedure includes important aspects of the catalyst manufacturer’s start up procedure for that particular catalyst in the unit’s HDP reactor. The unit’s start up procedure will highlight key steps or conditions to follow and highlights what to avoid in order to not compromise (i) the safety and (ii) the relative volumic activity of the catalyst. Check to see if you have an operating procedure specifically written to start the unit for catalyst sulfiding. If not, consider writing a specific procedure to guide the operators. This will give you the opportunity to review and allow you to include key aspects of the catalyst manufacturer’s start up procedure.How does control of the DMDS chemical flow help optimize the complete activation once primary sulfiding is attained?

The amount of H2S generated on the catalyst from DMDS is directly proportional to the flow of DMDS. Optimizing the DMDS flow optimizes the amount of H2S in the recycle gas, which many refiners define to be >5000 ppm. Additionally, controlling the exotherm by controlling the DMDS flow rate, allows one to adhere to the 500/hr temperature rise of the catalyst, prescribed by the catalyst manufacturer. All of this combined results in an optimally sulfided and activated catalyst.Note that some units are furnace limited. Some unit engineers have used the DMDS as a supplemental heat source to raise temperatures and reduce the time needed to get to the secondary sulfiding phase.

What are my biggest challenges during my sulfiding?

The temperature during the secondary stage is usually > 500 °F, thus high enough to cause the reduction of the catalyst. Therefore, the value of H2S in the recycle gas should not be less than about 5000 ppm to be on the safe side. Modulate DMDS injection to maintain the above value of H2S without exceeding the maximum temperature rise prescribed by the catalyst manufacturer.The advantage one has with DMDS is that one can control the exotherm by adjusting the injection

rate. Maintaining prescribed temperature increases(~50 °F/Hour), having a steady flow of DMDS,

maintaining at least 5000 ppm H2 and 60+% H2 in the recycle gas are some of the challenges. Most importantly, purging the recycle gas to ascertain no issues with molecular weight induced tripping of the compressor is essential.