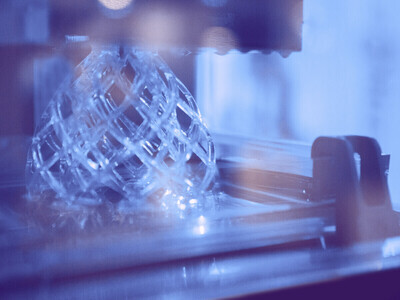

Sartomer® Specialty Urethane Oligomers for 3D printing

Arkema continues to drive the future of additive manufacturing with a range of 3D printing oligomers to deliver the right balance of mechanical performance, reactivity, and surface properties across every formulation need — from flexible and impact-resistant resins to rigid and high-temperature materials.

As additive manufacturing evolves, formulators are redefining what’s possible — and materials are at the heart of that transformation. Sartomer® UV-curable oligomers deliver the building blocks for resins that combine precision, durability, and advanced performance, helping innovators push boundaries in 3D printing.

Whether you’re targeting rigid, flexible, or toughened systems, our oligomers are engineered to deliver:

- Tailored mechanical properties for structural and functional parts

- Optimized reactivity and viscosity for faster print speeds and smooth surface finish

- Enhanced stability and durability under UV and thermal stress

- Durable performance, enabling long-lasting materials with lower processing energy

With our N3xtDimension® custom formulations and deep UV-curing expertise, Arkema can partner to develop the resins of tomorrow — from industrial prototyping to end-use manufacturing.

Explore our latest 3D printing oligomer literature and see how we are shaping the next generation of photopolymer performance.

Rigid oligomers

Rigid oligomers are beneficial in 3D printing formulations where high stiffness, dimensional stability, and durability are critical. Sartomer® oligomers enable the development of high-performance liquid resins with high tensile strength and glass transition temperatures, ensuring excellent rigidity, high-temperature resistance and long-term durability for demanding applications.

Tough oligomers

Developing 3D printing resins with high toughness and durability is critical for functional applications. Sartomer® tough UV oligomers are designed to combine strength with flexibility, enhancing mechanical performance to deliver resilient printed parts that can withstand impact, stress, and demanding mechanical environments.

Elastomeric oligomers

Sartomer® elastomeric oligomers enable the design of rubber-like, highly elastic resins with soft touch, rebound, and excellent tear resistance. These oligomers provide exceptional stretch and recovery for end-use applications requiring comfort, resilience, and design freedom.

Flexible oligomers

For resins that need bendability without permanent deformation, Sartomer® flexible oligomers deliver high elongation, impact resistance, and durability. They are engineered to create lightweight, resilient printed parts that can endure repeated use and moderate stress while retaining shape and performance.

Water resistant oligomers

Water-resistant UV oligomers enable the development of 3D printing resins that maintain mechanical integrity and performance even in humid or wet environments. Sartomer® solutions provide enhanced barrier properties and durability, making them ideal for functional parts exposed to moisture or challenging end-use conditions.

Low yellowing oligomers

Sartomer® UV-curable oligomers can deliver exceptional transparency and minimal yellowing — enabling vibrant colors, sharp details, and clean finishes across SLA, DLP, and LCD platforms. Whether you're formulating for high-resolution consumer goods, medical models, or display components, our low color oligomers offer the optical purity and formulation flexibility needed to meet demanding visual and performance standards.