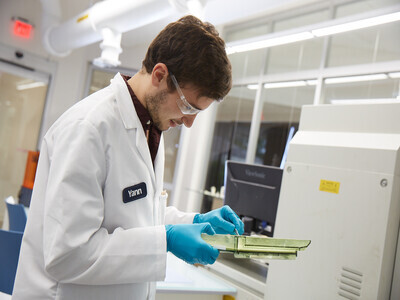

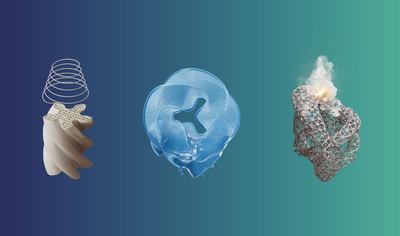

3D-printed eyewear frames made with liquid resin

Arkema and GENERA partner to bring 3D-printed personalized eyewear to the consumer goods market. The breakthrough solution paves the way for unmatched personalization, improved comfort and functional mechanical properties to complement the wearer’s style and preferences.

Summary & Key takeaways

Partner: GENERA

Industry: Consumer goods / Application: Fashion eyewear / Printing technology: Digital Light Processing (DLP) / Material: N3xtDimension® N3D-GEN976

Key takeaways:

- Innovative Collaboration: Highlighting the power of collaboration between GENERA and Arkema

- Customization: By leveraging 3D printing, manufacturers can now achieve unmatched personalization and a custom fit for wearers.

- Optimized Performance: The combination of tailored, high-performance materials and automated manufacturing has led to improved comfort, optimized mechanical properties and faster production of 3D-printed eyewear frames.