New Ocean Fifty Arkema trimaran: a genuine ocean racing racer!

2022: improvements and new design

“We laid the boat bare,” Quentin Vlamynck explains. “This enabled us to check all its structural components. In particular, we rectified a small weak point at the junction of the link arm. The roof was modified to make the living area better protected from the elements and more comfortable, though comfort remains quite a relative thing! Rather than sleeping on the floor of the deck, we fitted a small slightly raised bunk outside. This will really improve living conditions on board.”

The most visible change on the trimaran concerns its graphic design. In November 2021, the Arkema Group confirmed its positioning as an expert in innovative materials at the service of a sustainable world, with a new visual identity. “The boat looks very smart in its new colors, with warmer tones and a softer feel to it. I look forward to seeing the first visuals of the boat at sea!" Quentin continues.

Season 2021: an initiatory first season

For this first season of the Pro Sailing Tour, the new Arkema and its crew led by Quentin Vlamynck finished 2nd in the general ranking. A very good result for the first season of the circuit.

Quentin also took away a great deal from the Transat Jacques Vabre, as the youngest skipper in the Ocean Fifty class. He has now completed his first crossing of the Atlantic in a multihull, running against great, highly professional skippers.

Christening of Arkema

Quentin Vlamynck's Ocean Fifty Arkema was christened in Bordeaux on Monday 27 September 2021, one year to the day after its launch, and just a few weeks before its first Transat Jacques Vabre – Normandie – Le Havre race.

In the presence of Arkema employees involved in the construction of this innovative trimaran, and with the support of the boat’s honorary patron Pauline Déroulède, French Wheelchair Tennis Champion, emotions were running high in the splendid Capital of Wine.

A new philosophy in boat design

Designed by marine architect Romaric Neyhousser, Arkema is the result of a new rationale, shared with Lalou and Quentin, which transpires in the boat’s design.

Thanks to feedback from the former Arkema 1, Lalou Multi and his sponsor-partner Arkema have laid down a new framework. The first trimaran built by Lalou Multi was based on a short-handed crew at sea. This new boat Arkema has less typical features, is more versatile and more efficient for the crew as well as inshore. This has guided the choices regarding the platform, in particular for the “X” crossbeams (not parallel beams) used to optimize the ergonomics in crew sailing.

Versatility, the watchword for Arkema

Lalou Roucayrol sums up this versatility perfectly:

“Our aim was to build a more versatile boat than the previous one, in other words just as effective in in-shore crew events as in solo ocean racing. We have put much thought into the masses and improved the aerodynamic brakes. It’s going to be a powerful boat!”

Romaric Neyhousser, the boat’s architect, details the work that has gone into aerodynamics to enhance this versatility:

“The idea is to reduce the aerodynamic drag as much as possible, even more than on the other Multi 50. The objective is to profile all the shapes that produce drag, in particular for the crossbeams, but also to work on the sheet effect of the sails. The fairing adds weight, but we believe that the resulting gain will offset this additional weight.”

Skipper-focused ergonomics

Here too, there are many differences with the previous Arkema 1. The boat’s design makes it more versatile, but it must also enable the sailors to keep up the pace in all types of events, whether in crew sailing, solo sailing, in-shore or on the ocean. The cockpit offers greater protection in particular.

As Quentin Vlamynck, the skipper of Arkema, explains, “It’s vital to keep up the pace more easily sailing as a pair or solo, and to be able to go fast over a sustained period of time, including in challenging conditions.”

Performance: The inside story

As in the past, this new Ocean Fifty is the result of intense technical collaboration between Arkema and Lalou Multi. With recyclable resins, new materials, 3D printing of technical parts, clean energy, many features are indeed driven by innovation, and others will remain flexible throughout the sporting life of Arkema.

With a more spacious cockpit, Arkema offers greater protection for sailors than its predecessor.

1. Sails

Signed Incidence, clsely involved with the Arkema project since Pierre-Antoine Morvan, Match Racing European Champion and Technical Manager for Incidence sailmakers, will be the tactician for the Grand Prix. The gennakers, J2 and J3, are cable-less, therefore do not have any tension cable: the leading edge is thinner and the void better distributed. The fixture points are made of Elium®/carbon composite rather than aluminium, with the added benefits of lower weight and recyclability.

2. Deckhouse / Cockpit

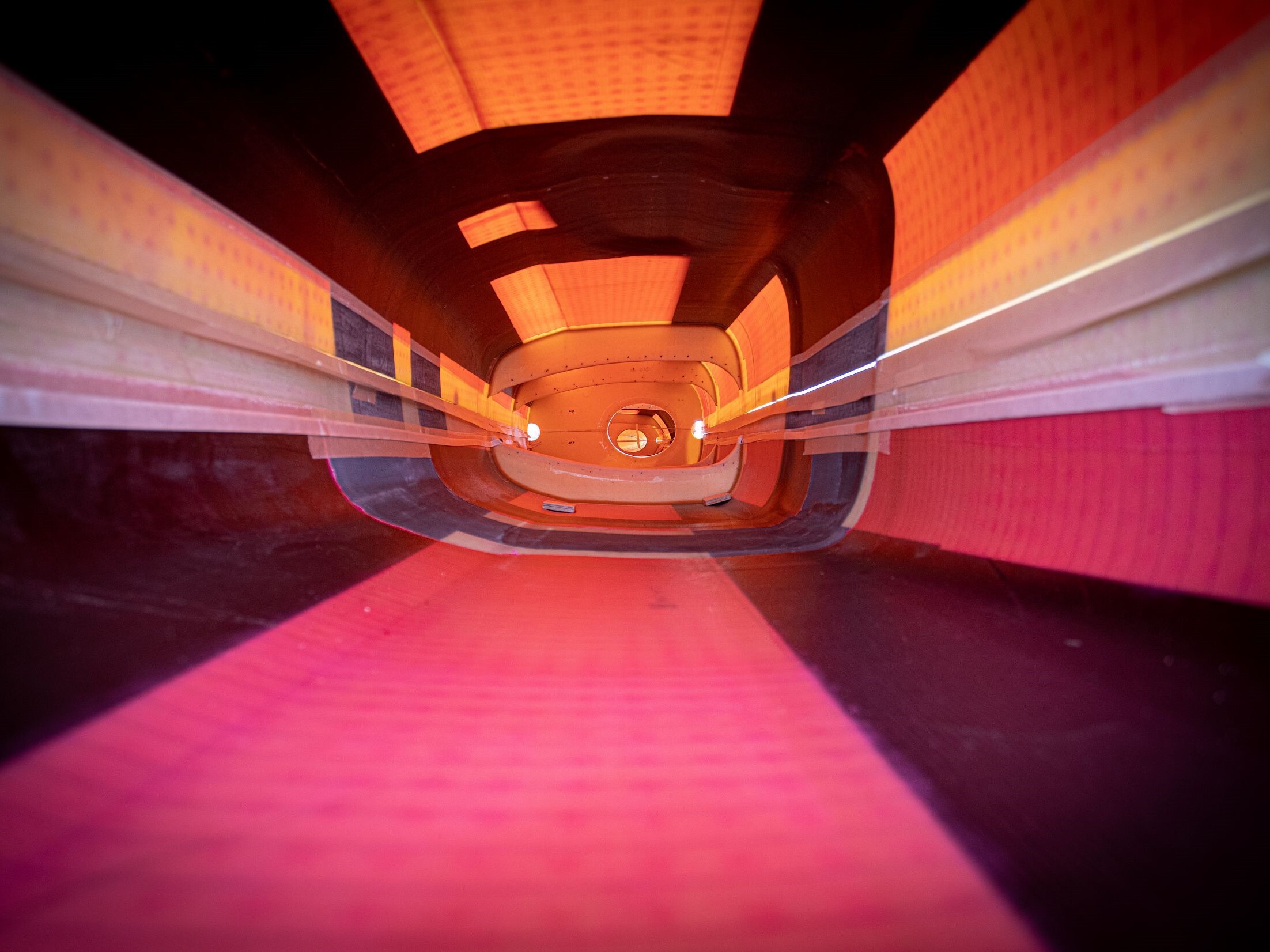

Completely recyclable and made entirely of composite based on the recycled Elium® resin. Approximately 80 cm lower than on the other Ocean Fiftys, the cockpit allows for sheltered maneuvering. For superior visibility whatever the sea conditions, cockpit and deckhouse are fitted with ShieldUp® Flex® PMMA glazing, the world’s first flexible sheet recently developed. This material’s flexibility makes it easy to install without thermoforming over substantial contours. This ”acrylic glass” is 5 times more impact-resistant than traditional PMMA. It also has an anti-scratch and water-repellent coating. The result: a remarkable and durable optical quality, even in challenging conditions, as well as a weight reduction of the order of 50%!

3. Energy

Latest-generation lithium batteries using Arkema’s Kynar® technology were selected. Developed by the young French company Powertech, they help increase energy storage capacity by 50%, with no increase in weight compared to Arkema 1. Combined with a larger surface of photovoltaic panels installed on the front outrigger arm, the system delivers fully autonomous energy supply to on-board equipment, without emitting a single gram of CO2.

4. Floats

The floats feature raised sections, but their volume is smaller than on its forerunner since the foil gives the necessary support. The dihedral angle (between outrigger and horizontal plane) has been increased to prevent the windward float from dragging in the water in light winds.

5. Central hull

Validated by many digital simulations (CFD), this hull is wide at the bridge to increase the sheet effect on the front sails. Below the waterline, it is deep with V sections for less bumpy sailing. The clear forefoot allows for more efficient rotations. As with the floats and the outriggers, the structure and bulkheads were assembled by structural bonding using methacrylate products from the Arkema subsidiary Bostik.

The construction of Arkema

Lalou Roucayrol and Quentin Vlamynck heavily involved in the construction

Both Lalou Roucayrol and Quentin Vlamynck were naturally heavily involved in the construction of Arkema, the former being in charge of running the project and an expert in Arkema materials, and the latter as the skipper of the boat.

I know it’s vital to be as close as possible to the construction work and be able to incorporate my technical choices in consultation with Lalou, Nicolas Coudrais from the design office, and Romaric Neyhousser, the architect. The philosophy of Lalou Multi is precisely to keep the skipper involved in the strategic choices.

The construction in pictures

Arkema materials have pride of place

Already present on the previous Ocean Fifty and the Mini 6.50, the Group's materials have pride of place on the new Ocean Fifty Arkema.

The Elium® thermoplastic resin, for example, has been used to manufacture a number of components, including the crossbeam mold that, recycled when construction was over. Other applications include an even greater use of the wide range of Bostik adhesives, the production of parts using 3D printing, and work on the batteries.

Bostik structural adhesives used on the Ocean Fifty Arkema make a major contribution in terms of lightweighting, toughness and durability.

“The work undertaken with the Elium® resin has been extensive and complements developments in other markets such as wind power. And the construction of Arkema was an opportunity for us to demonstrate the recyclability of composites made from this thermoplastic resin. This latest trimaran is also a superb showcase for other products from our Group, including Bostik’s structural glues that make a major contribution in terms of lightweighting, toughness and durability. We had R&D teams dedicated to this construction project to identify materials already applicable and others potentially so in the longer term. A racing boat like this new trimaran is a tremendous driver of brand image, but above all it’s a full scale laboratory that enables us to show and test the performance of our materials in real-life sailing conditions. A “materials demonstrator” that can be transferred to other application sectors.”

Gilles Galinier, Communication Vice President for the Arkema Group

New generation sails

Lalou Roucayrol has been testing equipment for sailmakers Incidence for years. The boat was fitted with a test sail – a Strong Luff gennaker – in the Grands Prix of the 2019 season and during the training sessions. The trials were clearly conclusive, as explains Pierre-Antoine Morvan, Head of R&D at Incidence Group: “It’s a sail without halyard, in DFi®, with many novel features. The major asset of the Strong Luff, as its name suggests, is the performance of the luff, but also a significant improvement in overall performance. It’s lighter, more versatile and more dynamic.”

In order to extend the innovation of this new sail, Lalou Multi has decided to go ahead with manufacturing various fittings for these sails from the Elium® resin developed by Arkema. César Dohy, Master Sailmaker at Incidence, explains: “To hold these sails, there are two highly specific fittings called lugs. These are triangular aluminum parts measuring about 10 cm² with head and tack that literally secure the sail. Made from the Elium® resin, they are therefore lighter, with softer contours, and are now recyclable. Quentin and Lalou tested them in the Canary Islands, and the initial feedback was convincing.”