Chain Transfer Agents

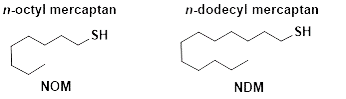

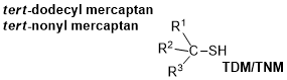

Mercaptans are commonly used as reactants in the manufacturing processes of many common rubber and thermoplastic materials. The use of mercaptans allows for fine control of the molecular chain length during polymerization, leading to easy processing conditions and mechanical performance of the resulting polymer.

- Africa

- Asia Pacific

- Europe

- Latin America and the Caribbean

- Middle East

- North America

- Oceania

Related products

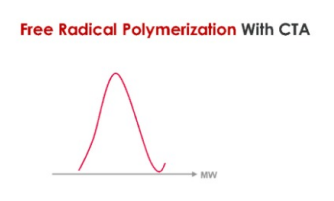

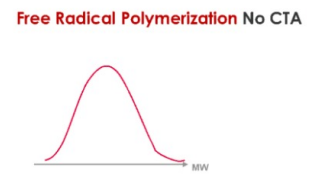

Using a chain transfer agent enables a narrower molecular weight distribution, leading to easy processing conditions and enhanced mechanical performance of the resulting polymer.

Arkema provides a range of chain transfer agents:

|

Heavy Mercaptans:

|

|

|

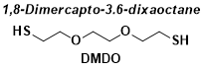

Polythiols:

|

|

|

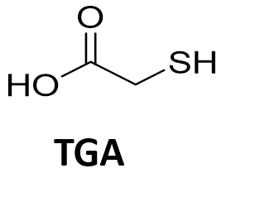

Thioglycolic Acid:

|

|

Supporting our customers is Arkema’s highest priority

That’s why we have built a team of specialized scientists who are experts in providing you with the right solution.

Our team is ready to assist you in recommending the best CTA for your process, developing new applications and for any general troubleshooting needs.

Please contact us to tap into Arkema’s unmatched expertise today.

How to choose the right chain transfer agent?

It is recommended that you choose your chain transfer agent based on the physical properties that are required for the material, as reviewed below.

Properties of final materials:

|

Constraints of process:

|

|

|

|

Choice of CTA:

|

|

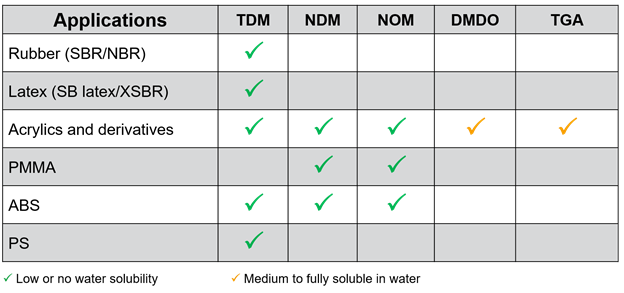

A wide range of applications

Material's Performance

Arkema’s chain transfer agents are heavily used by customers in a variety of polymer manufacturing processes in a wide array of industries, such as automotive, adhesives, rheology modifiers, and many many more. These processes include the production of polymers such as the ones based on butadiene and styrene (rubber and latex), the styrenics, the acrylics and derivatives PMMA and ABS), and the PS.

Several factors affect a material’s performance, such as the polymerization recipe, the polymer structure (molecular weight and MFR sensitivity), and the material performance properties, including service temperature, MFR, mechanical properties, product consistency, and thermal stability.