Composites solutions for lightweighting materials represent one of Arkema’s main research vectors. The Group today offers innovative solutions for recyclable high performance composites geared for the automotive and wind power sectors.

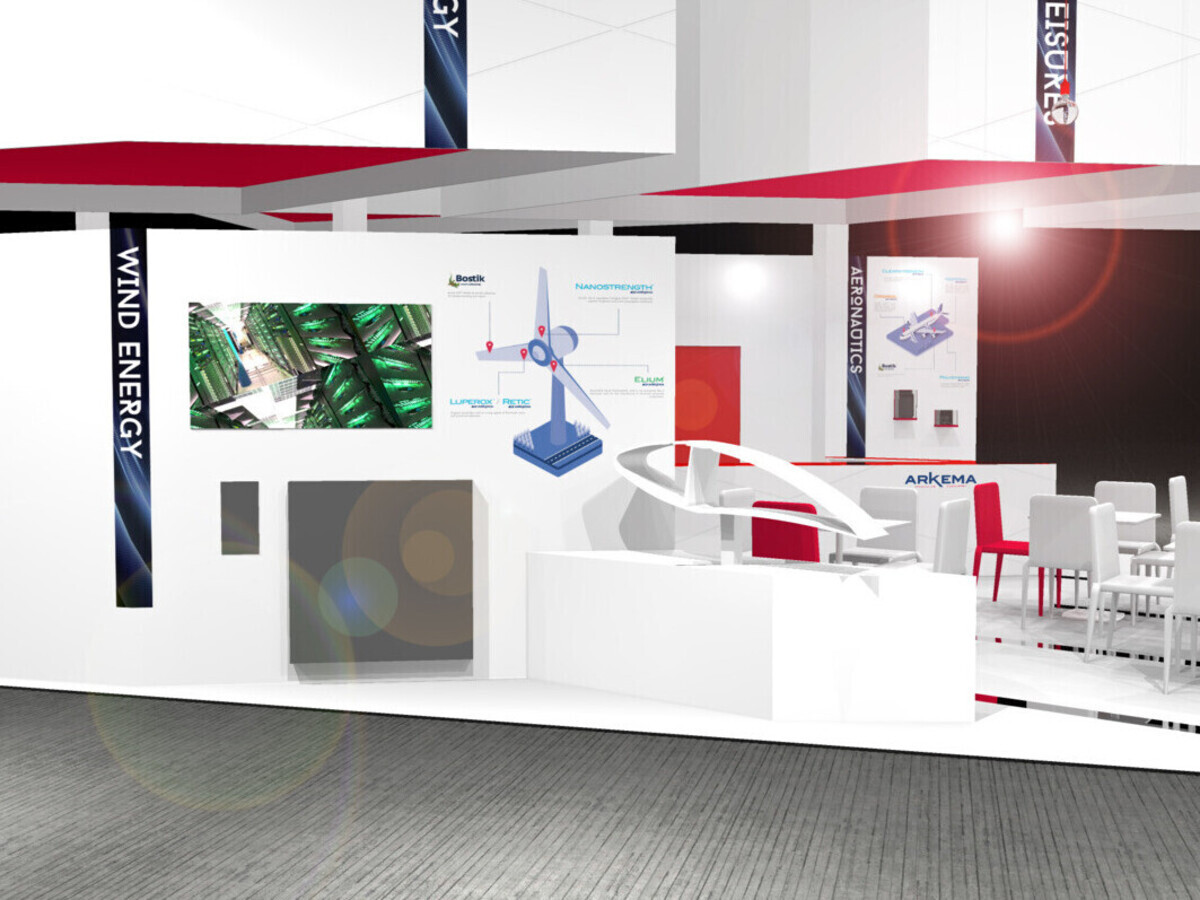

The JEC World 2017 tradeshow, to be held in Paris - Villepinte from 14 to 16 March, will showcase Arkema’s latest composites innovations (Stand U39 – Hall 5).

At the service of carmakers

Saving weight in order to reduce fuel consumption and recycling end-of-life materials are key issues for the transportation sector. According to European regulations, CO2 emission ceilings per car will go from 130 down to 95g/km by 2020*. Carmakers are also required to use 95% of recyclable or reusable materials in their vehicles.

Elium®, the strength of a composite, the recyclability of a thermoplastic

Combining mechanical strength and recyclability, Arkema’s Elium® resin allows the manufacture of thermoplastic composite parts that can replace metal. The resulting parts feature identical mechanical properties to thermoset parts. They are 50% lighter than steel, with the added benefit of being thermoformable and fully recyclable.

The Elium® resin offers a further key asset, namely its processing suitability using the automated mass production of parts without the need for subsequent finish machining (“net shape” process), therefore meeting the high production throughput demanded by the automotive industry.

This process, FAST RMT (FAST Resin Transfer Molding), developed in partnership with the IRT M2P platform in Metz, northeastern France, has earned Arkema a JEC Innovation Award, to be presented at the trade show on 15 March.

Rilsan® Matrix, the latest development from Arkema’s research into lightweighting vehicles

Arkema is pleased to announce the launch of our new Rilsan® Matrix series of high temperature, high performance polyamide resins especially designed for light weight automotive composites. These resins are filled with either carbon fibers or glass fibers and are supplied in the form of unidirectional tapes which enable the manufacture of composite parts using new and innovative processes designed for the high output requirements of this industry. For several decades, Arkema has been a world leading producer of high performance long chain polyamides. This latest development is a proud step forward for our famous brand.

Clearstrength® XT100, an innovative core/shell impact modifier for thermoset applications

Clearstrength® XT100 is a Methacrylate-Butadiene-Styrene (MBS) core/shell impact modifier. It is designed to meet the most demanding technical requirements of thermoset applications such as structural adhesives (e.g. methacrylates, epoxy…) and high performance composites.

Clearstrength® XT100 is particularly recommended to increase the toughness and/or adhesion of high performance thermoset formulations. It can be advantageously use to replace conventional core/shell modifier powders but also liquid masterbatches containing pre-dispersed core/shell particles.

Designing the wind turbines of the future

In order to meet environmental challenges as well as energy needs, global wind power capacity is steadily growing: over one million tons of composites are used every year to manufacture wind turbine blades. However, these blades made of thermoset composites (epoxy or polyester) are not easy to recycle at their end of life stage. To meet this challenge, Arkema has developed Elium®, the first liquid thermoplastic resin using the same process and equipment as thermoset composites, namely infusion.

Wind turbine blades made from Elium® have the advantage of being recyclable, thermoformable and thermoweldable, this latter property helping to limit the use of epoxy glues.

A first 9 meter wind turbine blade has been manufactured from the Elium® thermoplastic resin in the United States jointly with IACMI (Institute for Advanced Composites Manufacturing Innovation).

Initial tests carried out by Arkema have shown that a component made from the Elium® composite features a resistance to fatigue 10 times greater than components made from thermoset composites.

“We have indeed demonstrated the industrial viability of the project. Elium® is today the only thermoplastic that can accommodate the conventional tools and processes used to manufacture turbine blades” explains Michel Glotin, Materials Scientific Director at Arkema.

Another decisive milestone will be reached with the upcoming manufacture of a 25 meter turbine blade as well as the installation and commissioning later this year of a wind turbine fitted with Elium®

A major and renowned player in thermoplastic composite materials, Arkema continues its development work, involving collaboration with many public and private partners around the world.

*Press release from European Parliament – 02/25/2014