Fluid transfer systems

Over the past 60 years, fluid management systems have greatly contributed to the 90% reduction of light vehicle emission levels. The development of more efficient materials favors the advancement of new technologies limiting consumption and emissions. Truck and car manufacturers as, well as Tier 1 automotive suppliers, succeed in reducing the amount of part assemblies, therefore reducing their weight, and decreasing the phenomenon of evaporation while maintaining a high level of reliability and safety.

As a historical partner in the automotive industry, Arkema is at the forefront of innovation in high performance solutions. We have advanced in the development of thermoplastic tubing as well as crosslinking agents for EPDM for fluid transportation for under-the-hood and fuel system applications. Our solutions feature an outstanding balance between performance, cost and secure supply, always anticipating new trends and constraints of the evolving automotive market.

High performance thermoplastics

Our dedicated teams of experts are commited to the development of new specialty polyamide solutions for monolayer and multilayer tubing used in fuel line applications. We offer a wide range of cost-effective solutions to meet OEM specific application needs.

Fuel line solutions

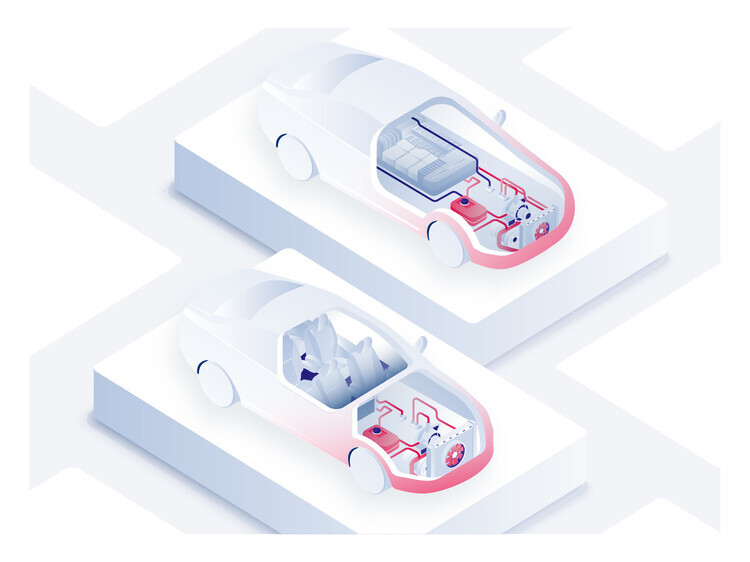

Lower emissions, cleaner fuel, and higher temperatures are the primary challenges OEMs face in the development of new generation vehicles to address changing customer requirements for more sustainable vehicles.

For over half a century our long chain polyamides such as Rilsan® PA11 and Rilsamid® PA12 have proven success in thermoplastic fuel lines due to their high flexibility, excellent mechanical performance and exceptional chemical resistance. Our high performance solutions help to resolve highly challenging tasks and are adhere to the most stringent specifications.

Fuel system connectors

Reducing the number of components, cutting the number of assembly steps, reducing costs while guaranteeing a high level of reliability; these challenging tasks can be answered with our full range of long chain polyamides and alloys.

Rilsan® HT is a flexible polyphtalamide (PPA) material is an excellent fit for metal replacement in fuel system applications. The material is compatible with all kinds of process technologies, ranging from extrusion to blow or injection molding. The product facilitates high function integration when used as quick-connectors in combination with flexible Rilsan® HT tubing. Rilsan® HT injection grades - glass-fiber reinforced or formulated for conductivity - are ideally suited for metal replacement in fuel system applications requiring low permeation, low swelling and high thermal resistance.

Emission control systems

New systems for next generation vehicles, such as exhaust gas recirculation (EGR), crankcase ventilation, or selective reduction of the catalyst (SRC) require a high level of chemical and thermal resistance. Automotive Solutions by Arkema provides long chain polyamide materials that are ideally suited to the most demanding OEM specifications.

Arkema offers a range of products adapted to the constraints in vacuum control lines or turbocharged ventilation systems as well as SCR Lines and Tanks.

Focus on... our wide range of high performance polymers that withstand extreme conditions

The ecological awareness, the increased strictness of regulations, the acceleration of technological developments and the evolution of mobility are all challenges that our customers must face.

With globally recognized expertise in the automotive market, we offer our customers a wide range of advanced materials and high performance polymers enabling them to innovate and continue to grow their business.

Case study - Automotive

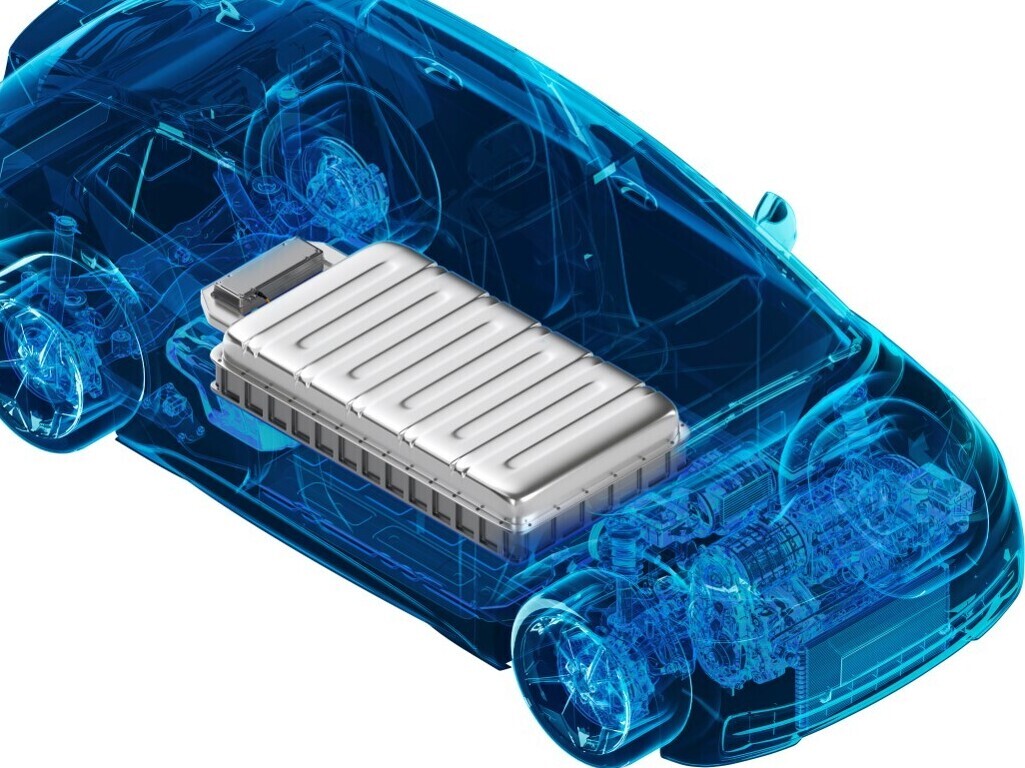

Producing low wash out high performance conductive fuel lines for hybride cars and beyond with Rilsan® PA 11

Crosslinking agents for EPDM parts

Arkema provides a comprehensive range of organic peroxide formulations for crosslinking specialty rubbers used in automotive applications. Organic peroxides create strong carbon to -carbon crosslinked bonds that are identical to the carbon to -carbon bonds in the backbone of the elastomer itself. Organic peroxides are the ideal crosslinking agents to enhance the mechanical and heat ageing properties of elastomers.

Radiator hoses, brake hoses, steam-hoses

Arkema Luperox® organic peroxide product range provides rubbers and elastomers with outstanding mechanical, thermal, and chemical resistance. It allows manufacturers to meet demanding requirements such as good heat ageing properties, resistance to Electrochemical Degradation (ECD), low compression set at elevated temperatures and high modulus/high elongation. Luperox® organic peroxides are easy to mix in a formulation and easy to store long-term.

O-Rings and gaskets

Arkema Luperox® organic peroxide enhance the properties of EPDM rubber (Ethylene Propylene diene monomer) imparting high resistance to heat, fuel and methanol, and motor oils. EPDM is used to manufacture O-Rings and gaskets used in various under-the-hood components. Automotive Solutions by Arkema has recently introduced Luperox® AIR® XL80, an innovative free-flowing formulation for curing EPDM compounds used in a wide range of applications including various molded parts. AIR® technology offers the flexibility to cure EPDM compounds in the presence of air and provides tack-free surfaces upon curing.