Nov 16, 2020 - 5 min

Printing large pieces in small series for drinking water application with Rilsan® PA11

3D Printing Solutions by Arkema present a case study on French industrial product design company Novall that successfully manufactured turbine body in small series.

Introduction

Novall is a French company specialized in mechanics, mechatronics engineering and industrial product design. The company has an entity dedicated to additive manufacturing that designs and produces small series adapted to exceed the stringent demands of their customers. Novall aims to develop tailor-made solutions for highly demanding applications by using cutting-edge technology and engineering expertise.

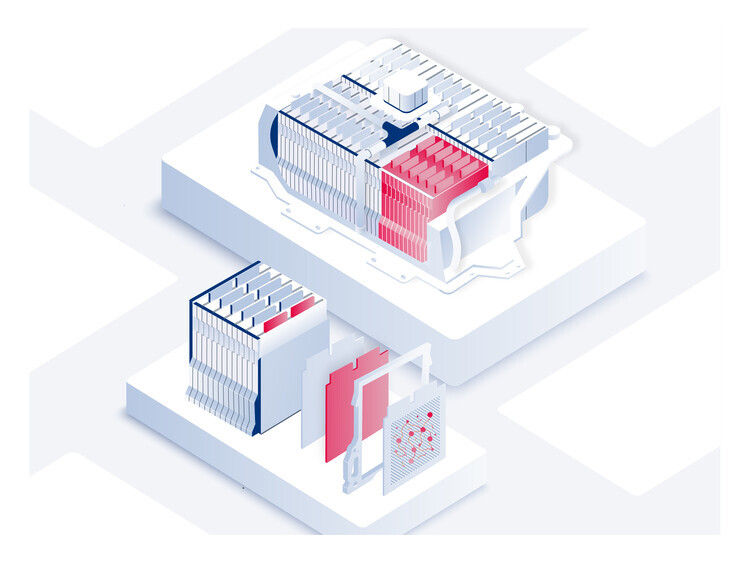

Novall partnered with Save Innovations, a family sized business that designs, manufactures and markets innovative solutions to meet the energy challenges of the future. Save Innovations aims to provide solutions that bring intelligence to drinking water networks by supplying electric power to real-time data collection devices. Energy is the cornerstone of all systems and energy demands are growing constantly. Alternative and renewable sources are a solution to this problem. Together, Novall and Save Innovations developed small series parts for the turbine used in the pico-generators which enable the efficient operation of these intelligent drinking water systems.

Summary

Industry: Water management

Application: Body of turbine for pico-generators in water supply systems

Objective: Creating complex large parts can be costly for small series production. Novall opted for additive manufacturing to reduce production costs. They also needed a material to produce these parts that met the challenging mechanical requirements as well as the necessary regulatory approvals for direct contact with drinking water.

Printing technology: Laser sintering

Material: Rilsan® Polyamide 11

Partner: Novall www.novall.fr

See also

Back to all articles- Expertise articles

Expansion of additive manufacturing: 5 cases of industrial application

- Expertise articles

Arkema takes up the challenge of the circular economy with its high performance polymers

- Expertise articles