Sep 19, 2023 - 5 mins

Mass balance solutions to accelerate the shift towards more circular solutions

Today, the imperative to reduce GHG emissions and move to a more circular economy has permeated across industries. Many companies are now committed to implement concrete actions to meet their sustainable development objectives and demonstrate their ability to shift to more resilient models. In the design phase, one of the challenges is to replace virgin fossil feedstocks by feedstocks coming from biomass or recycled origins while keeping the same high level of performance. The mass balance approach is a virtuous method to accelerate the transition and allows capex intensive value chain the access to renewable feedstocks with drop-in solutions.

This article delves into the realm of mass balance and its transformative potential within the industry. We will explore its core principles, highlight the benefits it offers, and underscore the importance of collective action throughout the entire value chain.

The challenge of replacing fossil feedstocks

Replacing virgin fossil feedstocks is a crucial step to reduce CO2 emissions linked to a product. By doing so, we can tackle climate change, preserve valuable resources, foster circular economy principles, and meet the growing demand for eco-friendly products. Several methods exist to support this shift. Alongside the segregated model*, mass balance approach allows industries to gradually shift towards more sustainable alternatives.

What is mass balance?

The concept of mass balance has been used in various industries for several decades. The principle of balancing inputs and outputs to track material has been a fundamental concept for a long time. In the last decade, the concept of mass balance has gained increased attention in the field of renewable energy and more recently in the field of circular materials. The system has been endorsed by multi-stakeholders including NGOs, research organizations, industry associations and brand owners.

Like in the "renewable" electricity field, the principle of mass balance allows the overall share of renewable or recycled feedstock to increase in the industry as demand grows. Even if consumers cannot guarantee that the electricity powering their homes or the product they buy comes solely from renewable sources, the more the demand grows the more the share of renewable sources added at the beginning of the circuit is growing.

Mass balance approach, how does it work?

One of the key advantages of the Mass Balance approach is that it doesn’t require any modification of the process, or new product accreditation as the high quality and performance of the products remain the same, which makes it easier for our customers to adopt them”

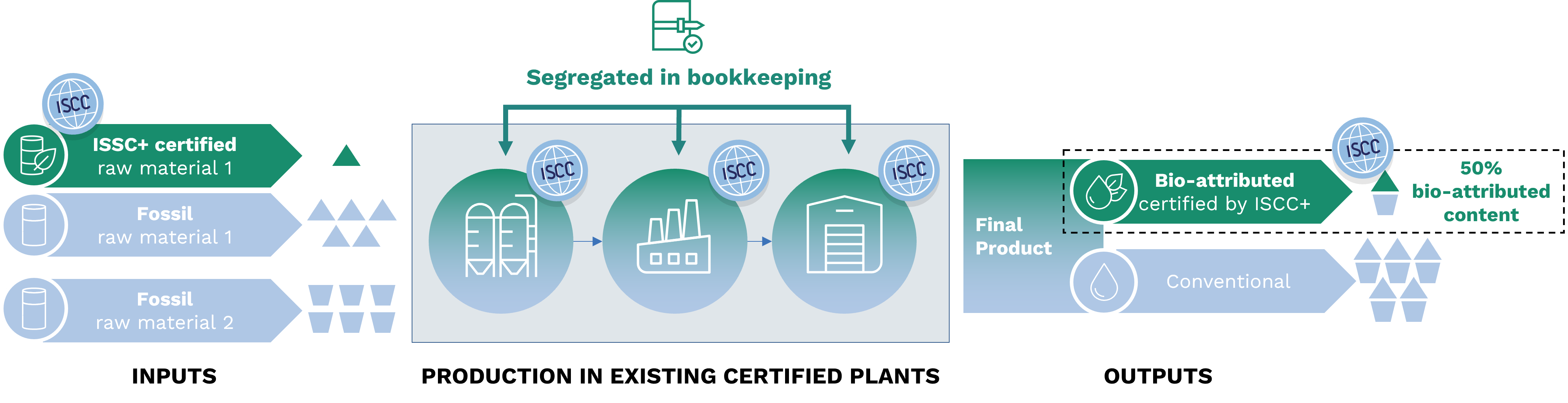

Let’s take a concrete example. At the origin of the supply chain, we substitute part of virgin fossil feedstocks by bio-based feedstocks. Then, we process both feedstocks in the same existing production assets, and the quantity of bio-based feedstock is segregated by bookkeeping to attribute this quantity to finished products at the end of the chain. We then speak about bio attributed materials. “One of the key advantages of the Mass Balance approach is that it doesn’t require any modification of the process, or new product accreditation as the high quality and performance of the products remain the same, which makes it easier for our customers to adopt them” says Jenny Klevås, Marketing Director at Perstorp.

Example of bio-attributed calculation

As explained before, fossil and bio-based feedstocks are mixed in same assets. That’s why at the end of the chain there is only one final product, but only a part of the production can be considered bio-attributed and benefit from ISCC+ sustainability declaration.

If a given quantity of certified bio-based feedstock is injected at the start of the chain, this given quantity will be eligible for the calculation of the share of bio-attributed. For this, the share of bio attributed content can be typically calculated following the rule below. In this example, output material is produced with 50% of raw material 1 + 50% raw material 2.

Raw Material 1: 100% bio-attributed content + Raw Material 2 fossil

= % of bio-attributed content = 50% certified by ISCC+ sustainability declaration on eligible volume

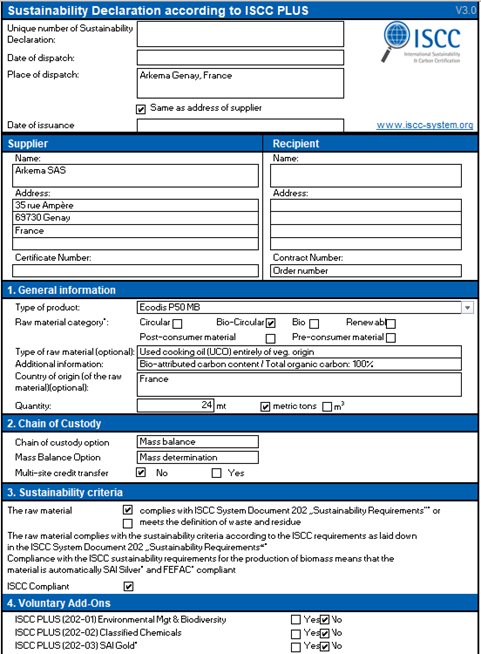

Certifying the traceability of this bio-based origin

As fossil and bio-based feedstocks are mixed in same assets, it is key to ensure a full traceability to the end products. The approach is framed by robust certification schemes applied across the whole value chain. Arkema entire supply chain is certified by ISCC (International Sustainability & Carbon Certification), a globally recognized certification system that promotes sustainability, traceability, and transparency across various industries, including agriculture, food, bioenergy, and chemicals. The ISCC+ certification of the whole supply chain guarantees that the origin of the renewable sources meets ISCC+ standards for sustainable feedstocks.

Hence, Arkema receives materials with ISCC+ sustainability declarations from its partners and provides its customers with ISCC+ sustainability declarations that guarantee the share of bio-attributed materials in Mass Balance products. The logic is the same until the last downstream stakeholder. If a final customer wants to claim the percentage of bio-attributed, he needs to be certified.

Example of EcodisTM P50 MB with only one monomer 100% bio-attributed

Example of EcodisTM P50 MB with only one monomer 100% bio-attributed

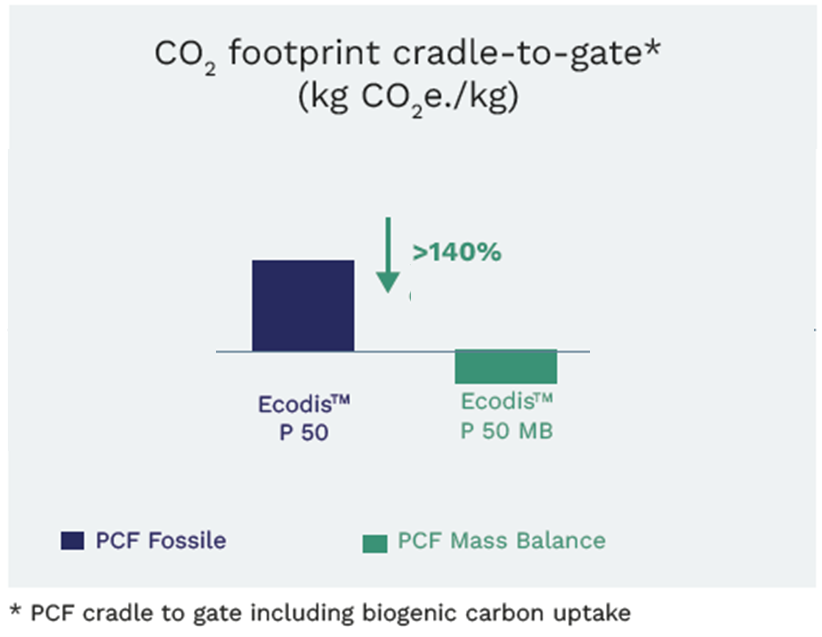

In addition of the ISCC+ sustainability declaration, the customer receives the carbon footprint of the fossil component and the one of the bio-attributed allowing PCF saving calculation.

Accelerating the reduction of GHG emissions through value chain collaboration

If we look at the example of the coating value chain, almost 40% of emissions are coming from the raw materials we buy”

Achieving sustainability requires a fundamental shift in collaboration and cooperation throughout the entire value chain. “If we look at the example of the coating value chain, almost 40% of emissions are coming from the raw materials we buy” says Mats Hägerström, EMEA sustainability leader at PPG. He adds “to reduce our CO2 emissions, we have an appetite to go beyond the traditional supplier/customer relationship and expect our key suppliers to propose solutions to decarbonize our supply chain”. For Hélène Pernot, head of Arkema Coating Sustainable offer “being part of a mass balance certified supply chain, like ISCC+, allows us to immediately reduce our own scope 3 emissions as well as the one from our customers while keeping the exact same level of performance. The framework of certification constraints all stakeholders to follow the same rules and enables a high level of traceability and transparency all along the supply chain”.

Significant opportunity to support product differentiation

If it is clear and proven that Mass balance can enable an immediate reduction of GHG emissions as bio-attributed materials are readily available , it also creates opportunities for product differentiation. When brand owners actively work to reduce carbon footprint, they can differentiate themselves from conventional offerings and create an enhanced value proposition for their products. By highlighting the reduced environmental impact, they offer consumers a tangible benefit beyond the core product functionality. This added value resonates with environmentally conscious consumers, further differentiating the brand's products from traditional offers.

*Good to know: what is a bio-segregated production?

As opposite to mass balance, a segregated production is a different model in which the bio-based materials are processed in segregated production lines. In this configuration, bio-based content can be measured by C14 analysis in final products. The two options are efficient ways to contribute to inject bio-based product in value chains and contribute to move away from fossil.

Conclusion

The transition from virgin fossil to renewable feedstocks, either bio-based or recycled, is a key priority to reduce GHG emissions and move to a more circular economy. Alongside the segregated approach, a system of mass balance attribution aligns with the urgent need to reduce carbon emissions in the industry and the growing demand for sustainable products. If moving toward segregated approaches can be considered as an ideal, mass balance serves an important step towards this objective. As a bridge pathway to a fully renewable approach, Mass Balance provides a fast, effective, and practical mechanism for incorporating sustainable materials while maintaining transparency and high level of technical performances.

To know more

Watch the presentation, Jenny Klevås and Hélène Pernot gave during the European Coatings Show 2023, into the essential role of traceable mass balance.

See also

Back to all articles- Case Study

- Case Study

- Case Study