Jun 19, 2023 - 2 mins

More sustainable coatings: leveraging alternative feedstocks

More and more consumers are aware of the impact of their consumption on the planet. They have a clear willingness to adopt a more sustainable and responsible lifestyle through the consumption of products with a reduced impact on the environment.

To meet these growing expectations, brand owners are moving away from fossil-derived materials toward materials coming from circular sources in order to preserve resources and reduce the impact on climate. The coatings sector is undergoing the same change and creating growth opportunities for bio-based coatings. To support this transition, we are engaged to accelerate the development of high performance resins and additives sourced from bio-based feedstocks by using the complementary approaches of physical segregation and mass balance.

Bio-based waterborne paints for interior walls

Challenge

In the rising demand for more sustainable products, consumers are not ready to compromise. One of the challenges of brand owners is to develop bio-based paints with at least the same level of performance as fossil-based products. To address this challenge, Arkema offers a full range of high-performance bio-based resins and additives. This use case illustrates that the combination of a waterborne alkyd resin made from 97% biobased raw materials with waterborne polyurethane thickeners enables formulators to create bio-based paints with a long lasting color strength. |

Lower impact on environment |  |

Safer |

|

Long lasting color strength |  |

Easy-to-clean |

Sustainable performance

|

SYNAQUA® 4856 is a waterborne alkyd resin made from 97% bio-based raw materials coming from byproducts of predominately Nordic foresting. It is APEO, ammonia, solvent and plasticizer free including low emissions suitable for many ecolabel paint formulations. |

| COAPURTM 3020 BB & COAPURTM 817 BB are polyurethane thickeners made from 90 & 93% bio-based raw materials to improve antisettling, leveling and application properties of the paint. | |

Technical performance

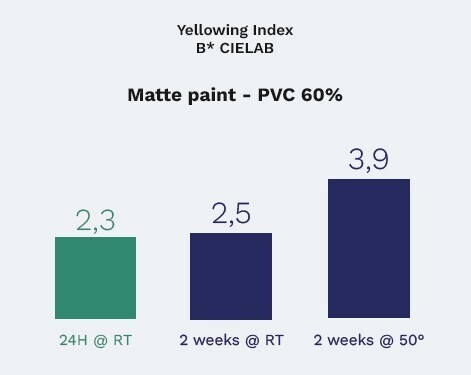

Low yellowing

Lower carbon footprint paint for interior and exterior applications

Challenge

Developing bio-attributed materials using a mass balance approach is an alternative pathway to meet the challenge of combining performance, circular sourcing and lower carbon footprint. In this approach, bio-based and fossil raw materials are produced in the same existing assets while the quantity of bio-based raw materials is segregated by bookkeeping at each step of the value chain. The sourcing can be implemented in the short term as bio-attributed products are drop-in solutions that enable the same level of high quality and performance without the need to requalify. |

Lower impact on environment |  |

Exterior durability |

|

Easy-to-use |  |

Easy-to-clean |

Technical performance

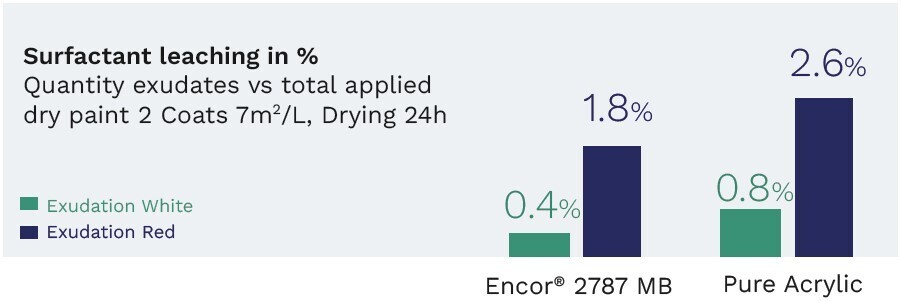

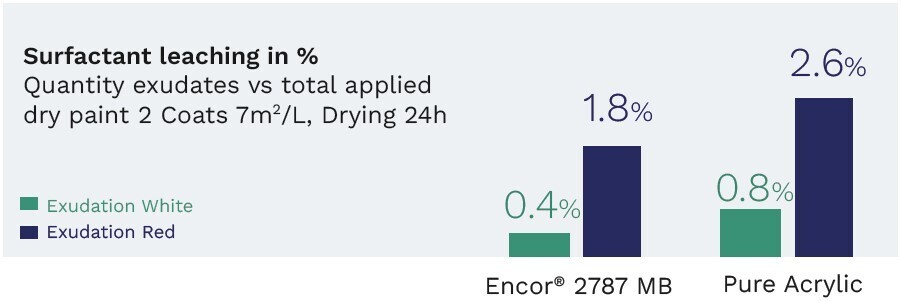

Excellent surfactant leaching resistance

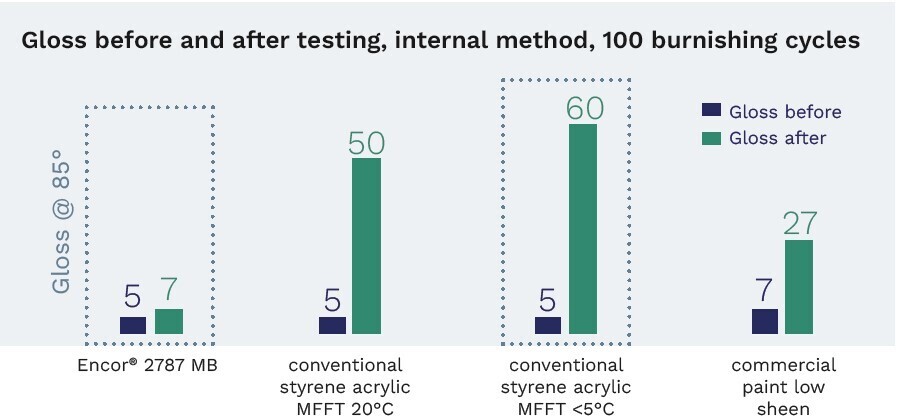

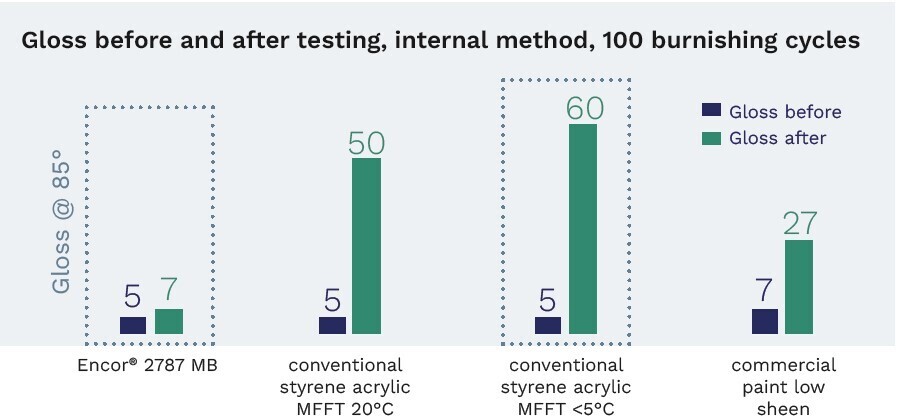

Improved gloss resistance (interior)

Excellent surfactant leaching resistance

Improved gloss resistance (interior)

See also

Back to all articles- Case Study

Producing low wash out high performance conductive fuel lines for hybride cars and beyond with Rilsan® PA 11

Mar 15, 2022

- Case Study

3D printed and tailor-made: orthopedic insoles made with advanced bio-circular polyamide 11

Mar 17, 2022

- Case Study

Producing battery cooling lines for hybrid and electric vehicles with Rilsan® PA11

Nov 12, 2020