Recycling of post-consumer waste is a major challenge for the plastic industry mainly due to the presence of a wide variety of polymers in waste streams. Recycled mixed polymeric blends usually have low compatibility, due to limited interfacial adhesion, which leads to poor mechanical properties and product failure. Improvements in the procedures in separating waste streams may lead to more effective recycling but those procedures are time consuming and rarely fully effective. Pressure from legislation as well as consumer more and more drive the industry to increase recycling rate and green initiatives.

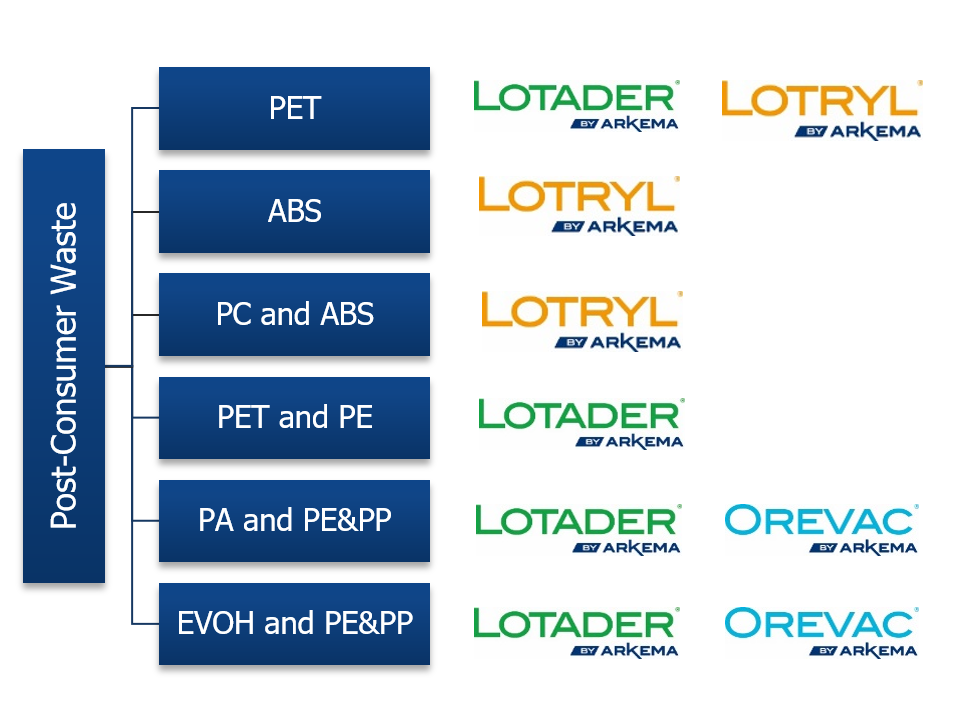

That is why Arkema has designed a full range of compatibiliser and impact modifier that allows mixed waste streams, targeting higher added-value applications. Lotader® reactive terpolymer, Lotryl® copolymer and Orevac® grafted polyolefins have been widely used for example as compatibiliser for multilayer structures based on polyolefins (LDPE, PP and HDPE) and engineering plastics (EVOH, PA and PET). Mechanical properties, and in particularly impact strength and elongation at break, are significantly improved opening up recycling opportunities in various extrusion and injection moulding applications.

A designer of materials and innovative solutions, Arkema shapes materials and creates new uses that accelerate customer performance. Our balanced business portfolio spans high-performance materials, industrial specialties and coating solutions. Our globally recognized brands are ranked among the leaders in the markets we serve. Reporting annual sales of €8.3 billion in 2017, we employ approximately 20,000 people worldwide and operate in close to 55 countries. We are committed to active engagement with all our stakeholders. Our research centers in North America, France and Asia concentrate on advances in bio-based products, new energies, water management, electronic solutions, lightweight materials and design, home efficiency and insulation. arkema.com