At the online JEC innovation awards ceremony, which took place today, Arkema was twice awarded with its partners for two major innovations in thermoplastic composites for aeronautics and railway applications.

High-performance welding technology for aircraft parts!

Arkema and The Institut de Soudure Group, in partnership with Hexcel, Latecoere and Stelia Aerospace won the 2020 JEC Jury Innovation Award in aeronautics category with their Innovative Solution for Welding (ISW) technology for thermoplastic composites.

This solution, jointly developed and patented by Institut de Soudure Group and Arkema, respectively expert in welding technology and expert in specialty polymers, provides very high performance welding for thermoplastic composites assemblies in aeronautics. The new process, first targeted at PEKK/Carbon composites for aerostructures, can be used for welding any thermoplastic reinforced with carbon, glass or aramid fibers.

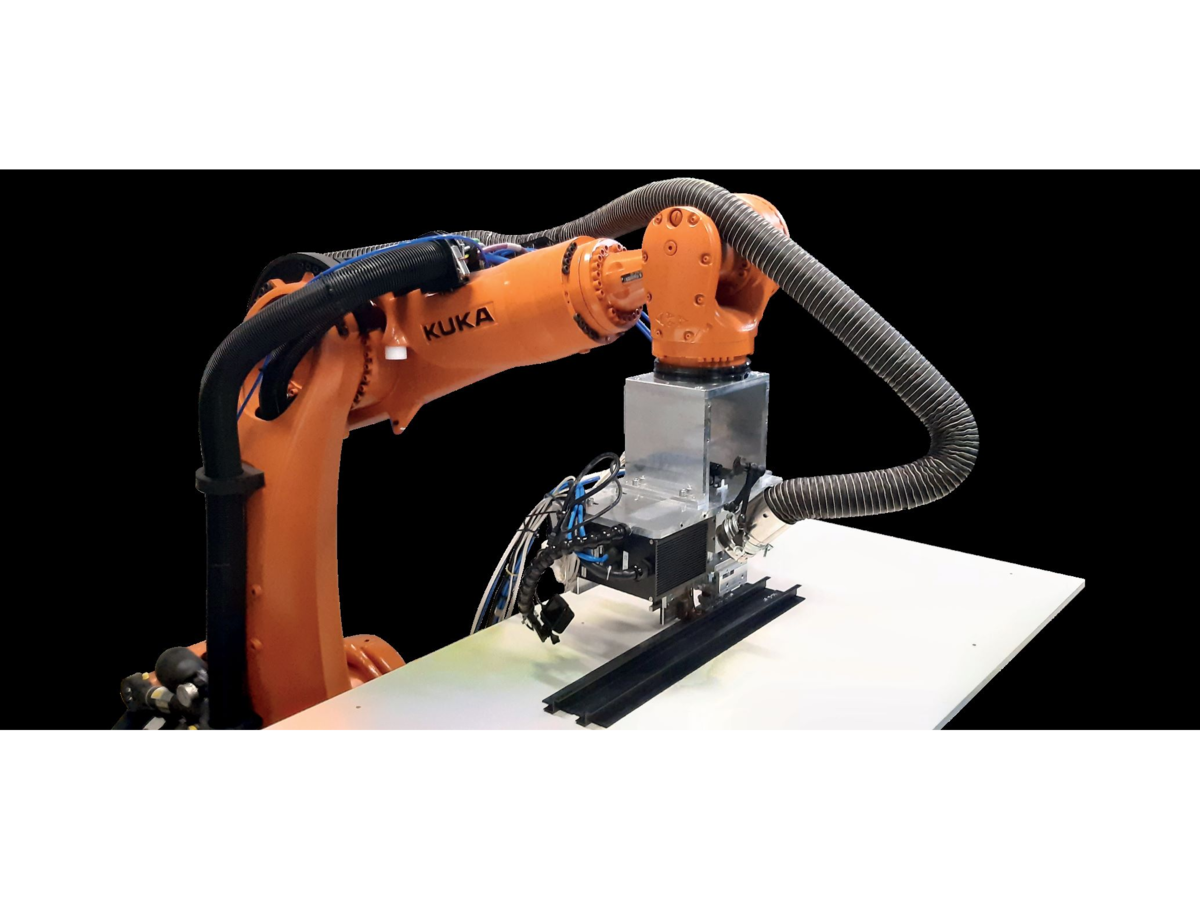

The development of thermoplastic composites in aeronautics is a big opportunity for the coming years, but in order to be cost effective, thermoplastic composite parts need to be assembled by welding rather than riveting. This innovative technology relies on the development of a robust process, based on a new dynamic induction welding head, which allows the composite assembly to reach the high performance targets set by OEMs and aeronautic parts manufacturers.

The innovative process offers outstanding benefits:

- A welding joint coefficient of about 85% compared to the reference composite material,

- Reduction of post operations,

- Reduction of weight,

- Dynamic and fully automated/monitored solution,

- Use of recyclable thermoplastic materials

- Low energy consumption due to a very localized heating

Hexcel, Arkema’s strategic partner for the development of thermoplastic composites for aeronautics, provided high-performance carbon fiber reinforced thermoplastic (PEKK) materials for the high quality welding targeted by the ISW process. From the beginning of 2019, some feasibility studies have been carried out with major aeronautic players such as Stelia Aerospace and Latecoere in order to evaluate the ISW solution.

From 2020, the main objective is to increase the maturity of the technology, applying it to specific aeronautics projects in order to lead it to a future aeronautic qualification.

Future trains in light and recyclable materials!

The second prize, the “Public Award 2020”, awarded by 25,000 voters, concerns the Destiny project carried out by Stratiforme Industries. With almost 60 years of experience, Stratiforme Industries has developed a train cabin in thermoplastic composite material, based on Arkema's Elium® resin.

As the traditional products in this field are thermoset composites, which are difficult to recycle at the end of their life, the development, manufacturing and certification of thermoplastic composite products meeting railway specifications is a real revolution for the sector. At a reasonable cost, it allows recyclability of the product at the end of its life. Until now, thermoplastic composite materials have been rarely applied to structural parts.

Stratiforme Industries counts among its operating and constructing rail customers such as SNCF, RATP, SNCB, DB, ALSTOM, BOMBARDIER, SIEMENS, CAF, PESA. This innovation has been carried out in partnership with Arkema, STELIA Aerospace, ASMA, CANOE platform, Crépim and IMT Lille Douai.

Stratiforme Industries counts among its operating and constructing rail customers such as SNCF, RATP, SNCB, DB, ALSTOM, BOMBARDIER, SIEMENS, CAF, PESA. This innovation has been carried out in partnership with Arkema, STELIA Aerospace, ASMA, CANOE platform, Crépim and IMT Lille Douai.