Jun 19, 2023 - 2 mins

More sustainable coatings: continuous progress for safer products

Among consumer expectations for a more sustainable lifestyle, Health & Well being is one of the first concerns. More and more digital applications scoring safety profile of consumer goods are developed to guide consumers toward informed choices.

For the coatings & ink materials, the elimination of substance of concern and hazardous air pollutants has been a long term trend which led to the conversion from solvent borne formulations to low VOC formulation such as waterborne, UV/EB and powder resins. Arkema has a pro-active approach to assess health, safety and environmental impacts of our products in order to anticipate future regulations and market trends. This approach leads us to propose a selection of profile products offering safety profile to further protect consumers, workers and community.

Ink for indirect food packaging

Challenge

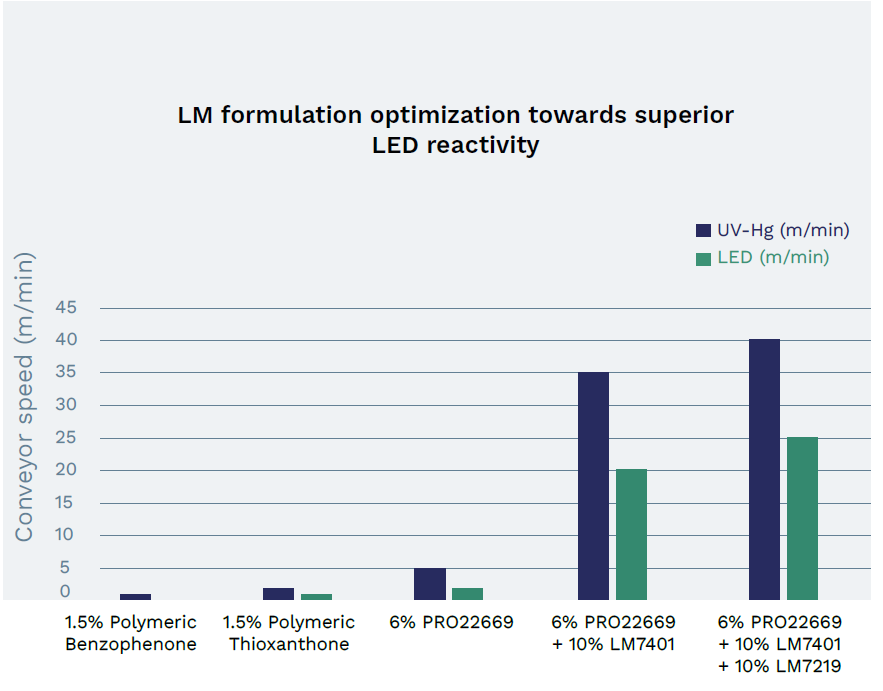

Consumers now place significantly more value on food safety and health. Designing food packagings with safety in mind is crucial. Printing inks and varnishes applied on packaging make no exception and have to combine high safety profile with high resistance during usage lifetime. Arkema is continuously innovating in this field to extend its product offer of low migration solutions for indirect food packaging. The latest grades include products combining multifunctionality, high molecular weight, and high reactivity under low energy curing LED systems. |

Safer |  |

Aesthetic |

|

Lower impact on the environment |

Sustainable performance

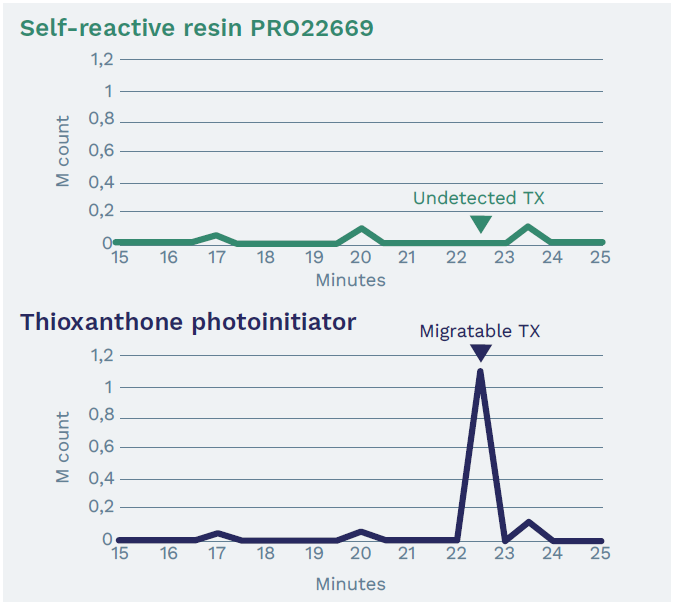

Reduced migration risk under LEDNo migration by set off and no migration through the packaging

Better compromise with no thioxanthone migration and low extractible acrylates

Technical performance

Better reactivity under LED

Improve health and safety of paint applicator

Challenge

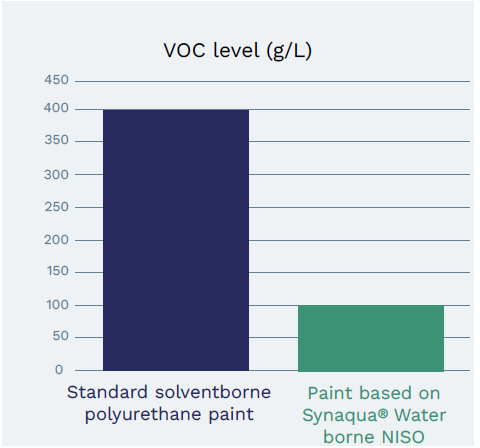

From decades, the coatings value chain has strived to achieve better performances while reducing substance of concern and hazardous air pollutants levels. Thanks to its complete portfolio of technologies including, high solid, waterborne, UV and powder, Arkema is definitely focused on the development of safer solutions with lower volatile organic compounds. In order to move one step further and anticipate future regulations, Arkema is continually exploring innovative solutions to improve the protection of consumers and the working conditions of paint applicators. This use case introduces a waterborne isocyanate-free system offering similar performance to a standard 2-pack polyurethane system with significantly lower VOC. |

Durability |  |

Safer for paint applicators |

|

High film thickness capability |

Sustainable performance

Low VOC Waterborne formulation & Isocyanate-free to protect paint applicators

Technical performance

Similar performance to a standard 2-pack polyurethane system

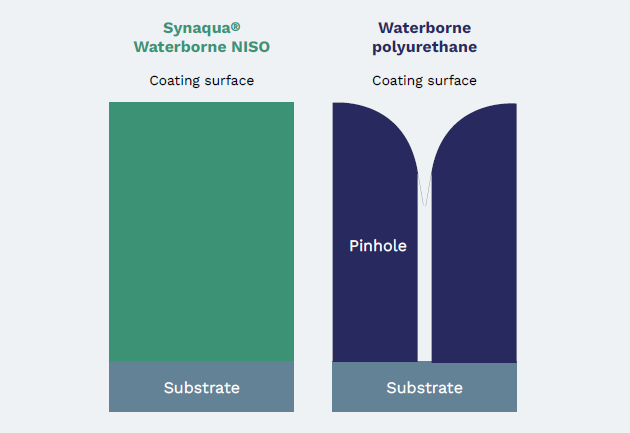

50% dry film thickness increase without pinholes vs. waterborne polyurethane

See also

Back to all articles- Case Study

- Case Study

- Expertise articles