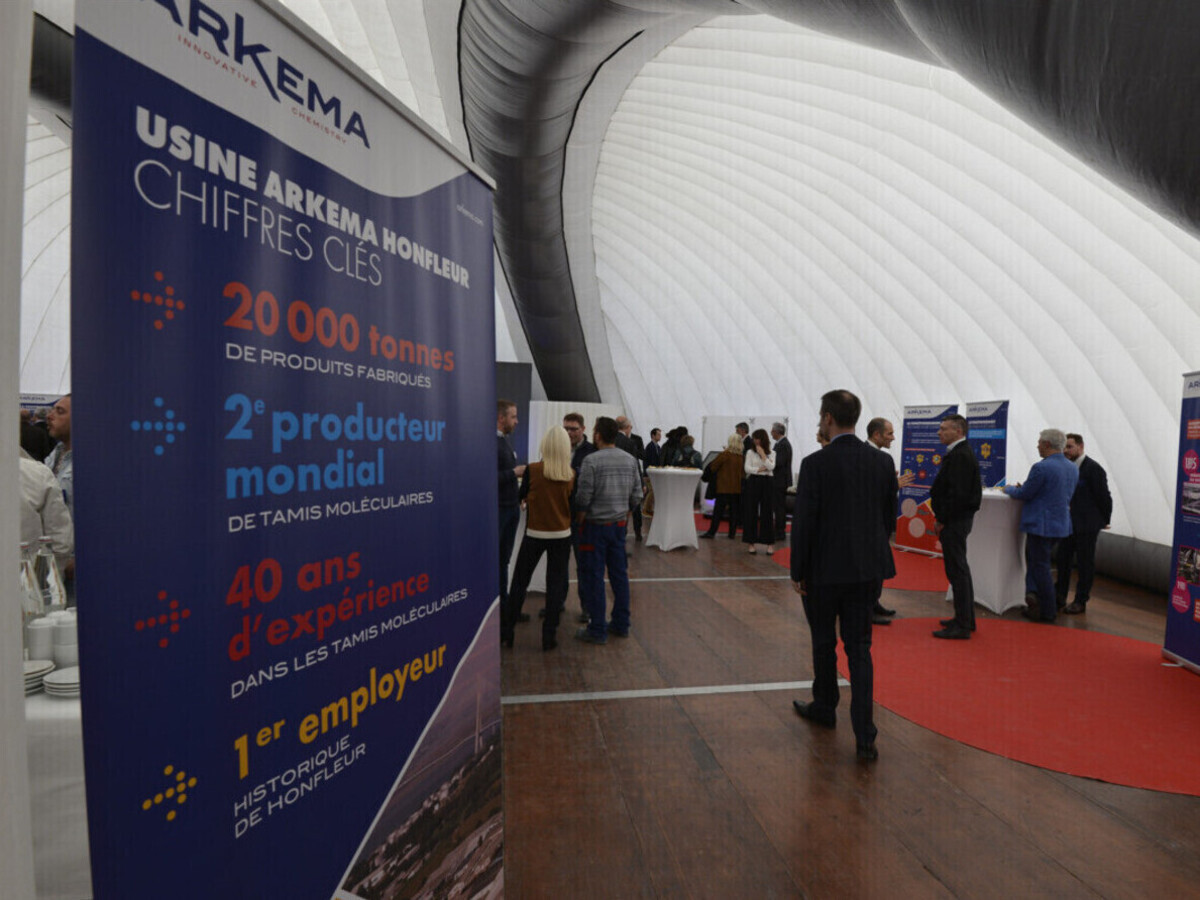

Thierry Le Hénaff, Arkema Chairman and Chief Executive Officer, inaugurates the new specialty molecular sieve capacity at the Honfleur plant today. This new plant will enable the Group to support its customers’ growth in the refining and petrochemicals markets, in particular in Asia and the Middle East. This investment of some €60 million supports the development of the High Performance Materials segment, represents one of the Group’s growth drivers, and consolidates its n° 2 world ranking in molecular sieves.

Arkema is the world’s second largest producer of molecular sieves. These products are used for their adsorption and dehydration properties, primarily in industrial gases and in some petrochemical plants, as well as in health (medical oxygen), construction, and pharmaceutical packaging applications.

The inauguration on the Honfleur site in France on Monday 24 April 2017 marks the official launch of the doubling of capacity for Arkema’s specialty molecular sieves dedicated to aromatics separation in petrochemicals, in particular xylene separation.

The new facility will enable Arkema to support its customers’ growth in the refining and petrochemicals markets, in particular in Asia and the Middle East, supplying the synthetic textile and PET bottle end-markets.

This new unit demonstrates Arkema’s expertise in specialty molecular sieves, while consolidating the IFPEN (IFP Energies nouvelles) / Axens / Arkema cluster of excellence in France for the supply of innovative technologies and solutions.

Representing an investment of some €60 million, this capacity extension concerns two ultra high performance molecular sieve plants producing in particular the latest generation Siliporite® SPX 5003. The plants came on stream in line with the planned timetable.

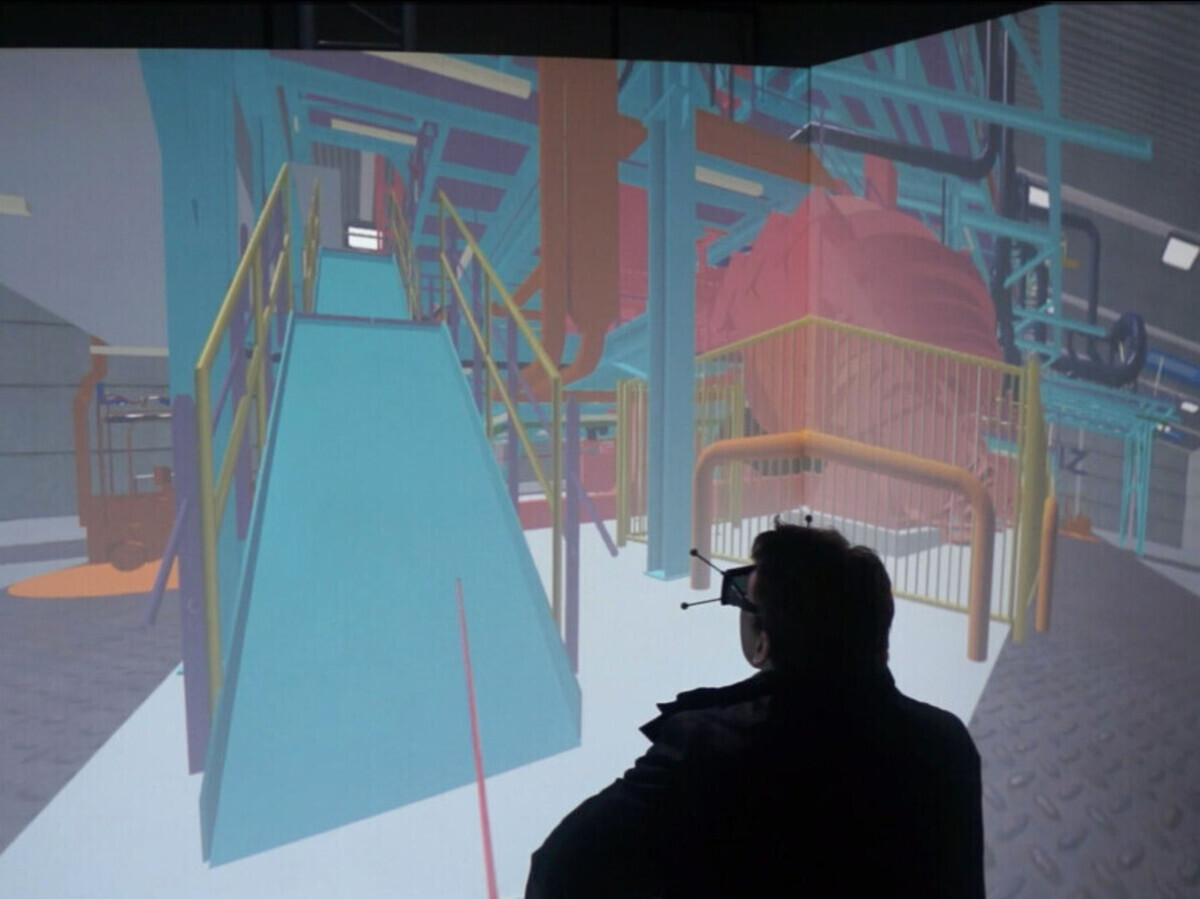

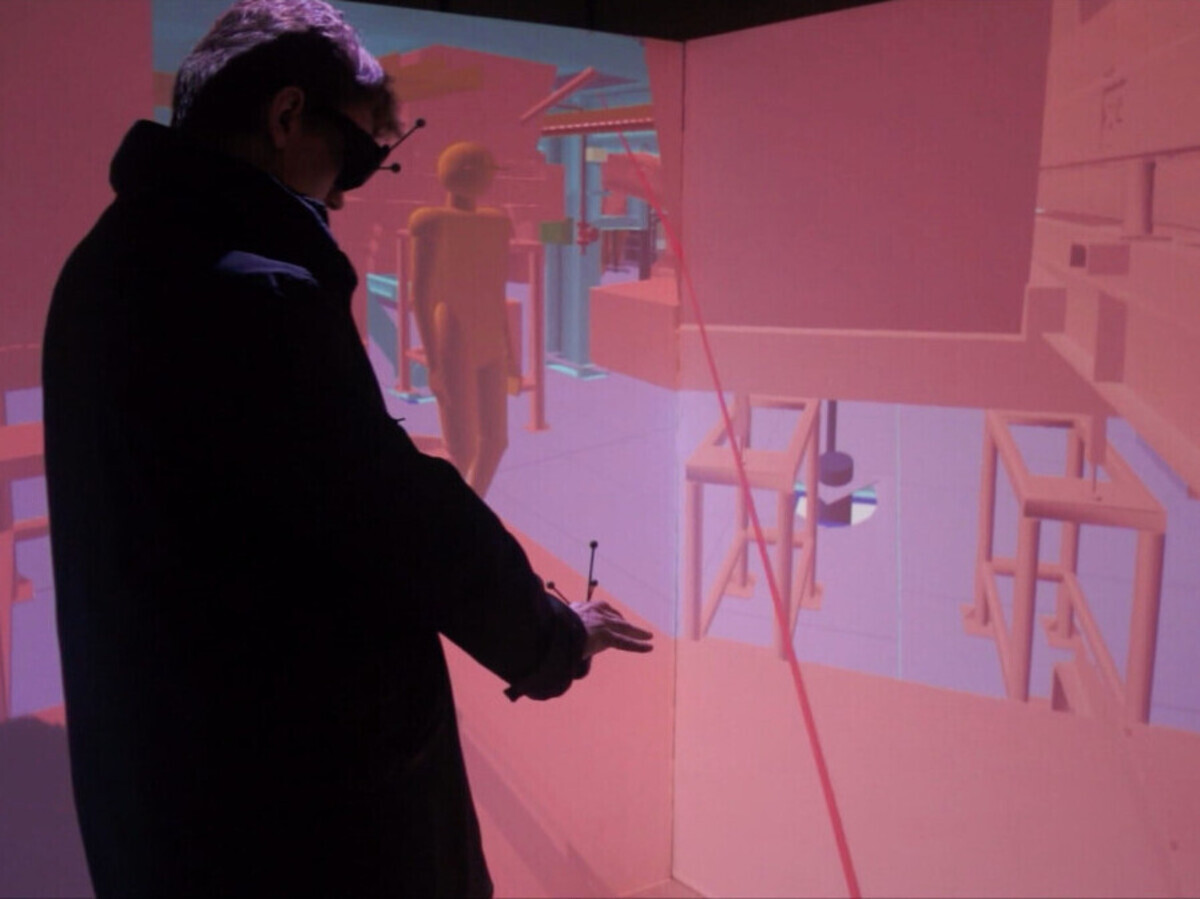

In line with the Group’s progress drive, the best available techniques chosen for these new facilities enabled to develop a new technology to optimize the recycling of the plant’s effluents. Furthermore, by using digital technologies, ergonomics and working conditions matters could be addressed from the project’s design phase.

With this project some fifteen direct jobs were created on the Honfleur site.

Usage de la 3D dans le projet et bien être au travail

Dès la conception de l'unité, la 3D a permis de travailler avec les opérateurs sur l'ergonomie et la pénibilité au poste de travail. 12 jours d'études et d'analyses de la maquette 3D ont généré 237 modifications !

- Un travail collaboratif de tous les acteurs du projet et du site

- Une démarche ergonomie et pénibilité avec les opérateurs dès la conception

- Un gain significatif sur la durée du projet

- Un contrôle de l'avancement de la construction en temps réel

- Une meilleure qualité de la construction