DMDS (Dimethyl disulfide), your reliable sulfiding and anti-coking solution

- アフリカ

- アジア・太平洋地域

- ヨーロッパ

- ラテンアメリカ・カリブ海地域

- 中東

- 北アメリカ

- オセアニア

関連製品

Your value-added partnership with Arkema, the worldwide DMDS supplier

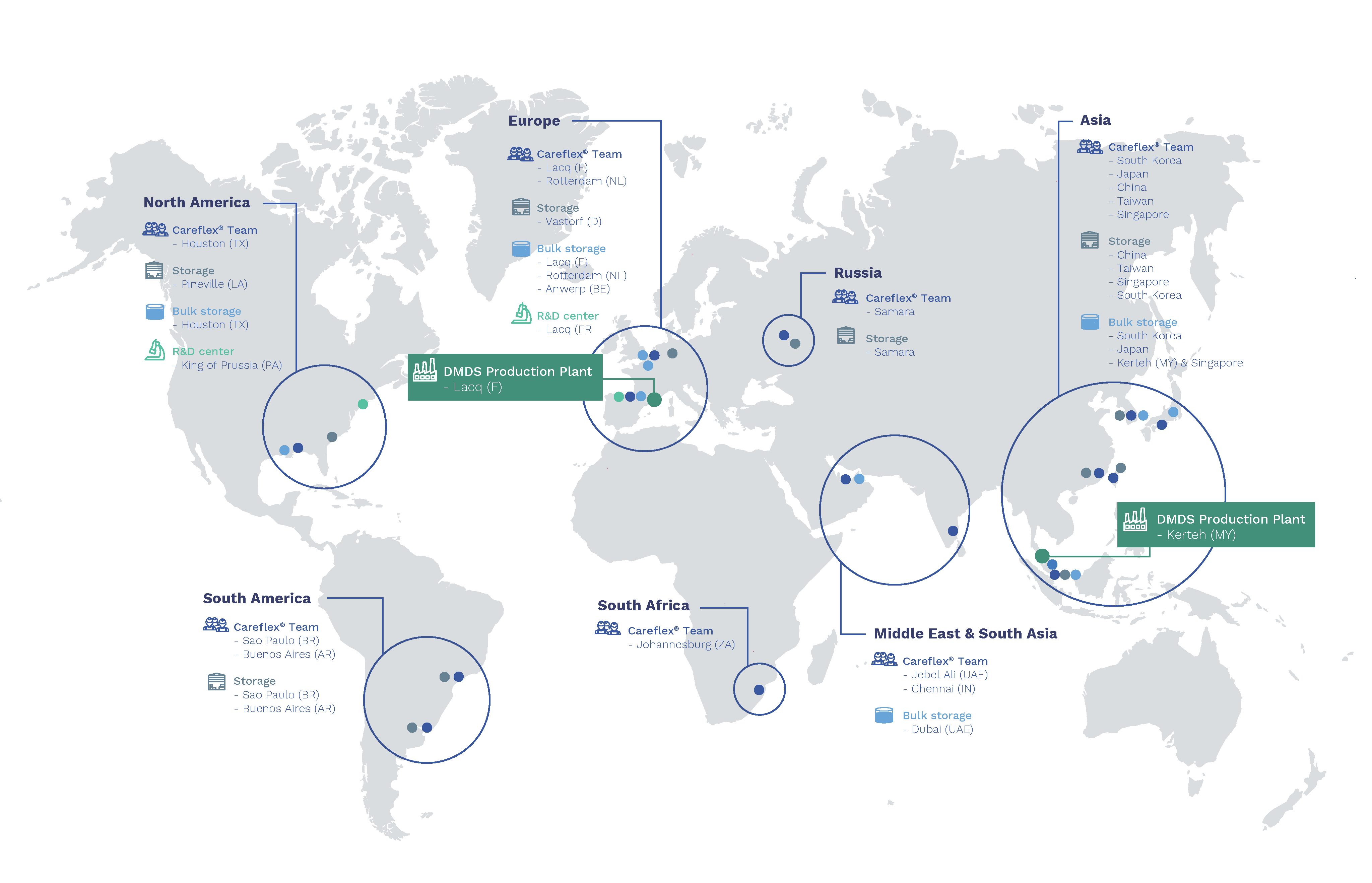

Our 40 years of experience producing high purity Dimethyl disulfide and multiple production sites together with distribution and bulk storage facilities located close to our customers ensure a fast and reliable supply to the major refining and petrochemical complex worldwide.

With decades of experience handling sulfur chemicals, our sales & technical network will provide you expert recommendations and will train your teams and provide you customized solutions for DMDS Evolution® E2 sourcing, storing, handling and injection.

A large fleet of returnable packaging semi-bulk containers (SBC] or iso--container is available for a safe transport and injection on our customer's site. Our Carelflex® teams will sulfide your hydrotreatment catalyst on time with the most reliable and efficient injection and monitoring equipment to resume production as planned.

Applications

Arkema is the only company to manufacture DMDS Evolution® E2, the standard sulfur derivative used by refineries, steamcrackers, propane & butane dehydrogenation plants and renewable diesel & Jet fuel manufacturers. It is critical for the process performance of these industries to have a secured and global access to a high and constant product quality. This contributes to quick and reliable unit startup as well as immediate on-specification production, which are the fundamentals of the refining and petrochemical industry performances and profitability.

An extended network and flexible logistic

A unique global logistics pattern

A unique global logistics pattern with a wide network of bulk storage tanks and warehouses close to the refineries and steamcrakers worldwide providing our customers with the shortest lead-time and safety of supply throughout the year. Our supply chain teams are local and meet our customer specific demand. More specifically, when our customers require DMDS injection during their turnarounds, our organization is flexible enough to reschedule to the last moment the product delivery and our Carelflex® teams mobilization and adjust it to the turnaround planning.

Trained & experienced local teams

Our Carelflex® teams are located close to our customers on all continents. Arkema meets MASE and VCA certification to operate in European refineries and in general all the safety and security training required by our customers all over the world. Our technicians and specialists with many years of experience, are provided with an extensive coaching program.