Jarytherm® heat-transfer fluids

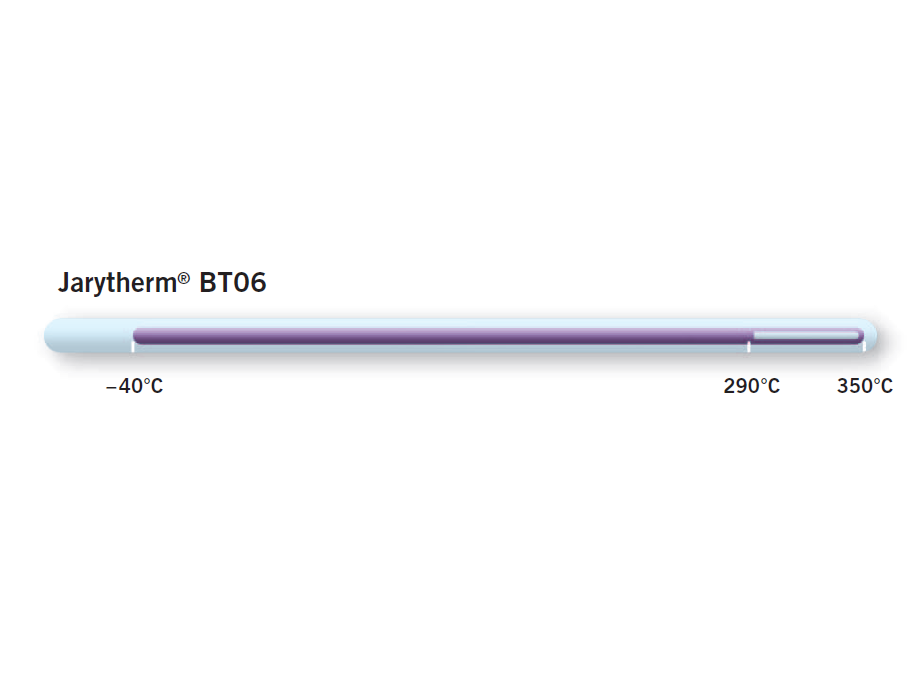

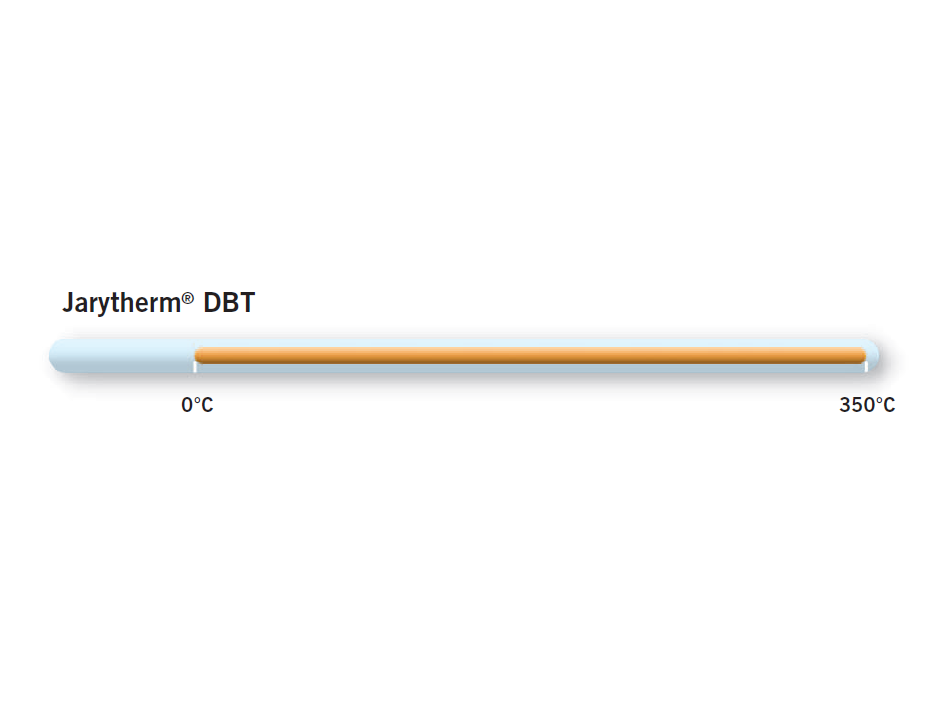

Jarytherm® products are 100% synthetic, high quality, heat-transfer fluids. They offer high performance between -40 and 350°C in applications such as distillation, heating of boilers, heating and cooling of reactors or storage tanks. Jarytherm® fluids are commonly used in the chemical and petrochemical, plastics and rubber, industries, pharmaceutical or fine and specialty chemicals industries.

- アフリカ

- アジア・太平洋地域

- ヨーロッパ

- ラテンアメリカ・カリブ海地域

- 中東

- 北アメリカ

- オセアニア

Why choose Arkema’s Specialty Technical Fluids

High performance synthetic heat transfer fluids operating in the range of -40° to 350 °C.

Download our brochures

High Performance Heat Transfer Fluid

- High thermal stability thus limiting product decomposition

- High flash point

- Low cold viscosity, reducing energy requirements and issues in case of shutdown

- Operates at atmospheric pressure over its temperature range, reducing capital expenditure

- Compatibility with all other thermal fluids which limit full change of the loading

- Well defined composition, easy to follow ageing

- Technical expertize for oil handling and in-service fluid analysis

- Reliable supply with high capacity storage tank in our plant

- Worldwide presence with dedicated technically trained sales team.

Clients benefits

Long-standing experience in heat transfer applications to meet the specific needs of every end-user around the world and ensure reliable operation.

Example of use for Polyamide production unit in China

System:

- Boiler running on natural gas

- Primary loop operating in the temperature range 300 – 320°C

- Total charge 12 MT.

Plant has been operating up to 320°C with Jarytherm® DBT for the past 17 years without any issue. This experience is supported by annual oil analysis.

Jarytherm® major applications

- Chemical and Petrochemical Industry

- Plastic and rubber industry

- Oil and Gas processing

- Refining

- Plastics and Polymer Manufacturing

- Synthetic Fiber Manufacturing

- Specialty and Fine Chemicals

- Pharmaceutical Industries

- Biofuel Manufacturing

- Energy recovery