Elium® thermoplastic resin for recyclable wind turbine blades

Elium® resin is a breakthrough innovation in composites materials. This thermoplastic resin provides many benefits for the manufacturing of large parts by resin infusion delivering similar performances to thermoset resins, or even stronger performance in terms of damage resistance, but with a key unique benefit: recyclability.

- Worldwide

Easy to use, improved productivity, performance has made of Elium® resin the missing link in the composite industry to replace thermoset resins that are hard to recycle.

With almost 10 years of development, tested by academic and institutional research groups all around the world, Elium® resin is now ready for the implementation in the wind industry.

A new 25 m blade manufactured from Elium® resin

Arkema has been working successfully with the Effiwind consortium to manufacture a new 25 m wind turbine blade. The infusion process used has helped validate the feasibility of producing on an industrial scale a very large blade from a thermoplastic composite.

Arkema is partnering with leading blade manufacturers and has developed a global supply chain on three continents to ensure the best quality.

Recyclability with Elium® resin can be achieved by:

- Mechanical recycling: composites parts like production waste or end of life parts are crushed into smaller part and heated into new composites panels

- Chemical recycling: that enable to separate the resin from fiber, depolymerize the polymer and to recover a new virgin resin ready to be reused, closing the loop.

Elium® resin: a disruptive innovation in the world of composites?

With its Elium® liquid thermoplastic resin, Arkema is bringing a unique solution to the market for the manufacture of composite parts, based on the same manufacturing processes as those used by fabricators to produce thermoset resin parts.

It offers the tremendous advantage of recyclability, but also of thermoforming and thermowelding. Many sectors could benefit from these key assets: wind energy, automotive, construction and sports.

The world’s largest 100% recyclable blade DNV-certified

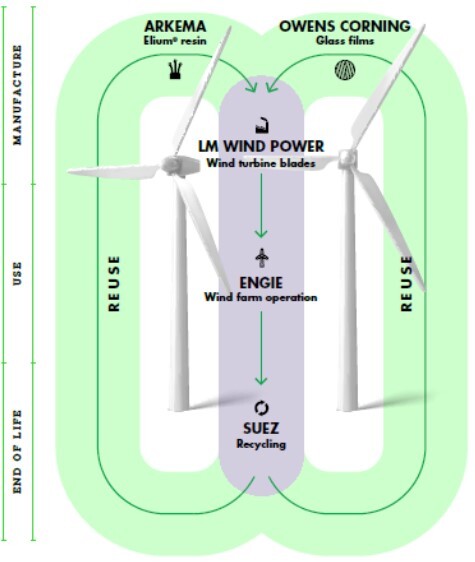

On March 2022, the ZEBRA (Zero wastE Blade ReseArch) consortium announced a new step forward in the industry’s ambitious transition project towards a circular economy with the manufacture of the first 100% recyclable prototype wind turbine blade using our Elium® liquid thermoplastic resin and new high performance glass fabrics.

Elium® has the unique potential to allow 100% of a wind turbine to be recycled.”

In addition to making wind turbine blades recyclable, Elium® resin has revolutionized how we produce them, more quickly and using less energy, as there is no need to heat the resin.”