Molecular sieves

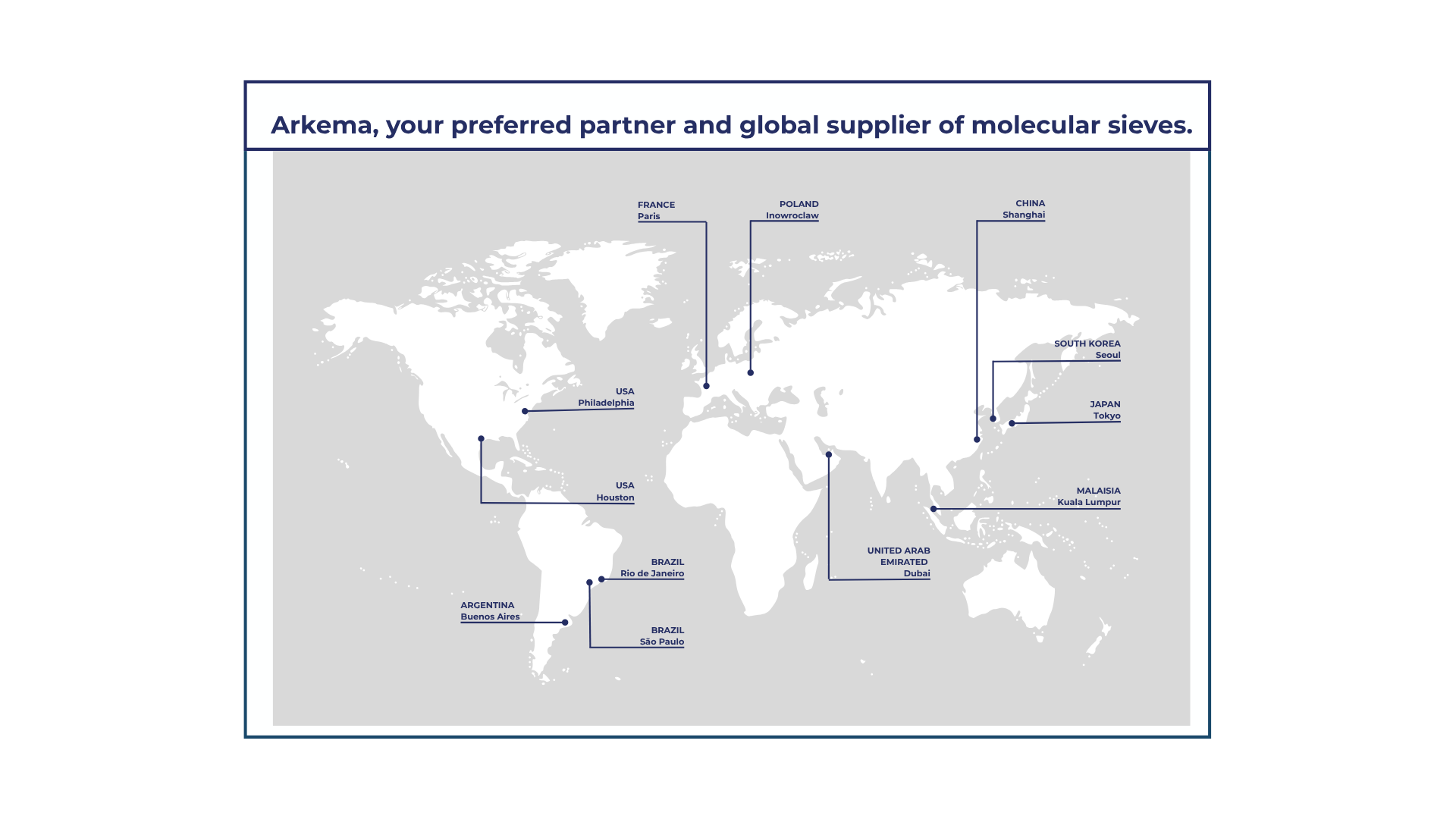

Arkema, your preferred partner and global supplier of molecular sieves

With cutting-edge expertise in technology, applications, and supply chain management.

With over 50 years of experience in molecular sieves, our experts are located in Europe, the United States, Asia, and the Middle East.

From design to manufacture, our molecular sieves are produced with a constant focus on quality in our own factories to guarantee performance and reliability.

Our international presence ensures the security of our supply chain, with warehouses and teams located around the world. We are able to anticipate and proactively respond to our customers' needs, wherever they are.

A comprehensive portfolio of molecular sieves for multiple applications

More than just a supplier, we are a committed partner offering a comprehensive range of customized support services including Siliporite®, Nitroxy®, Zeoclay®, Optisiev®, and Airsiev®.

ENERGY AND CHEMICALS

Siliporite® is an excellent choice for cracked gas units for drying olefins before the cold section.

Natural gas is produced under wet conditions and must be dried to protect downstream equipment, using a temperature swing adsorption (TSA) process.

MEDICAL AND PHARMACEUTICAL

Siliporite® is the benchmark solution for preserving the integrity of medicines in pharmaceutical packaging, effectively protecting them from moisture and degradation.

PU CASE

Siliporite plays a key role in polyurethane (PU) systems by removing residual moisture in isocyanates and polyols. Moisture control is critical to ensure proper curing, prevent foam defects, and enhance the durability of CASE (Coatings, Adhesives, Sealants, and Elastomers)

INDUSTRIAL GASES

The Airsiev® range is widely used for the production and purification of industrial gases such as oxygen and hydrogen. Molecular sieves are used for their nitrogen and oxygen separation properties in PSA/VSA processes, for their drying and CO2 adsorption capabilities in air pre-purification in ASUs, and for their purification properties in hydrogen production.

CONSTRUCTION

Molecular sieves are used in coatings to prevent bubble formation during formulation. Siliporite® molecular sieves for construction, in beads or powder form, are used to adsorb condensation between glass panes.

SUSTAINABLE SOLUTIONS

Siliporite® sustainable solutions contribute to energy efficiency and the reduction of greenhouse gas emissions, particularly in gas purification and CO2 capture.

Longstanding expertise in molecular sieve manufacturing

Our molecular sieves are available in a wide range of configurations: as powder, beads, or granules in various sizes. We also offer multiple packaging options, from small bags to large sacks, supersacks, and steel drums.

Arkema’s molecular sieves are consistently developed with a focus on reducing the carbon footprint of both our operations and those of our customers — feel free to ask us about our sustainability initiatives.

Our R&D capabilities at your service

Our R&D center, located in France, is equipped with several pilot units that replicate our customers’ processes at various temperatures, pressures, acidity levels, and more. This allows us to evaluate and enhance the performance of our zeolites for specific applications and to conduct tailored, effective studies for our customers.

Siliporite® molecular sieves contribute to four key UN Sustainable Development Goals:

- SDG 3 – Good Health and Well-being: by enabling clean oxygen production and protecting pharmaceuticals from moisture.

- SDG 7 – Affordable and Clean Energy: by optimizing gas purification in hydrogen and natural gas processes.

- SDG 11 – Sustainable Cities and Communities: through solutions that improve air quality and energy efficiency.

- SDG 12 – Responsible Consumption and Production: by promoting durable, regenerable materials with long service life.

Our CSR ambitions focus on three keys areas

- Arkema acts for the climate and the environment by reducing our ecological footprint to protect the climate and diversity.

- Contributing to people’s health and safety by improving their daily quality of life.

- Innovating to address social challenges by driving large-scale change in the industry.

FAQs about mol sieves and their use

1. What is a molecular sieve?

A molecular sieve, frequently called "mol sieve" is a microporous material, usually made from zeolites, modified silicas or activated carbons, with precisely controlled pore sizes. These pores allow molecules to be sorted according to their diameter and their polarity, acting as a selective filter at the molecular level.

2. What is the history of zeolites ?

Discovered in 1756 by Axel Fredrik Cronstedt—who called them “boiling stones” because of the bubbles they release when heated—natural zeolites were first used for drying and filtration.

In the 1950s, synthetic zeolites (types A, X, Y, ZSM-5, etc.) were developed, offering controlled pore size and composition. These materials quickly transformed the industry, particularly for catalytic cracking and air gas separation.

3. How does molecular sieve separation work?

Separation is achieved by molecular exclusion or inclusion. Molecules smaller than the pore size penetrate and remain trapped, while larger molecules are excluded. This mechanical selectivity guarantees separation based on the size and polarity of the molecules.

4. What are the main difference between 3A, 4A, 5A and 13X molecular sieves?

-

3Å molecular sieves (Type A, K-form)

Cation-exchanged 4Å zeolite (K⁺) with an effective opening of approximately 3Å. Only molecules smaller than ~3Å (water, NH₃) are adsorbed. Ideal for drying light alcohols (methanol, ethanol) without removing the solvent. Regeneration at 250–300 °C under vacuum or dry gas.

-

4Å molecular sieves (Type A, Na-form)

Sodium aluminosilicate with pores of ~4Å. Adsorbs water, oxygen, nitrogen, and linear hydrocarbons up to C₆, while excluding slightly larger molecules (e.g., longer-chain alcohols). Versatile use as a desiccant for air, industrial gases, solvents. Regenerated at 300–350°C under dry purge.

-

5Å molecular sieves (Type A, Ca-form)

Calcium-exchanged A-zeolite with pores of approximately 5Å. Adsorbs molecules ≤5Å, including CO₂, H₂S, NH₃, and linear or branched hydrocarbons up to C₆–C₇. Prized for natural gas purification (CO₂/H₂S removal) and gas dehydration. Regenerated at ~350°C under dry gas.

-

13X molecular sieves (Type X, Na-form)

Sodium X-zeolite (FAU) with pores of approximately 8 Å (opening ~10 Å). Very high capacity for CO₂, H₂O, H₂S and even aromatics or large organics. Used for volume separation (CO₂ from syngas or biogas), air separation (N₂/O₂), and drying of petrochemical solvents.

5. What applications use molecular sieves?

- Gas and liquid drying: removal of water or other unwanted impurities

- Air separation: production of pure nitrogen or enriched oxygen

- Solvent purification: dehydration and removal of heavy hydrocarbons

- Petrochemical refining: separation of xylenes, isomers or other fine fractions

- CO₂ capture: pre-treatment of gas streams for recovery or storage

6. How is a molecular sieve regenerated?

Regeneration involves removing the adsorbed molecules, usually by:

- Heating to high temperatures under vacuum or with a dry gas flow

- Rinsing with a cold gas to purge impurities

- Pressure cycling to expel the adsorbed fluids

These operations restore the adsorption capacity and extend the service life of the molecular sieve.