Innovative Materials, Arkema's R&D strategy

Innovate for sustainable development

Technological innovation is at the heart of Arkema's strategy and a key growth driver. It enables to address major economic and societal challenges through solutions that contribute to the United Nations Sustainable Development Goals and support the Group's customers in their quest for sustainable performance.

Support our customers to address their challenges

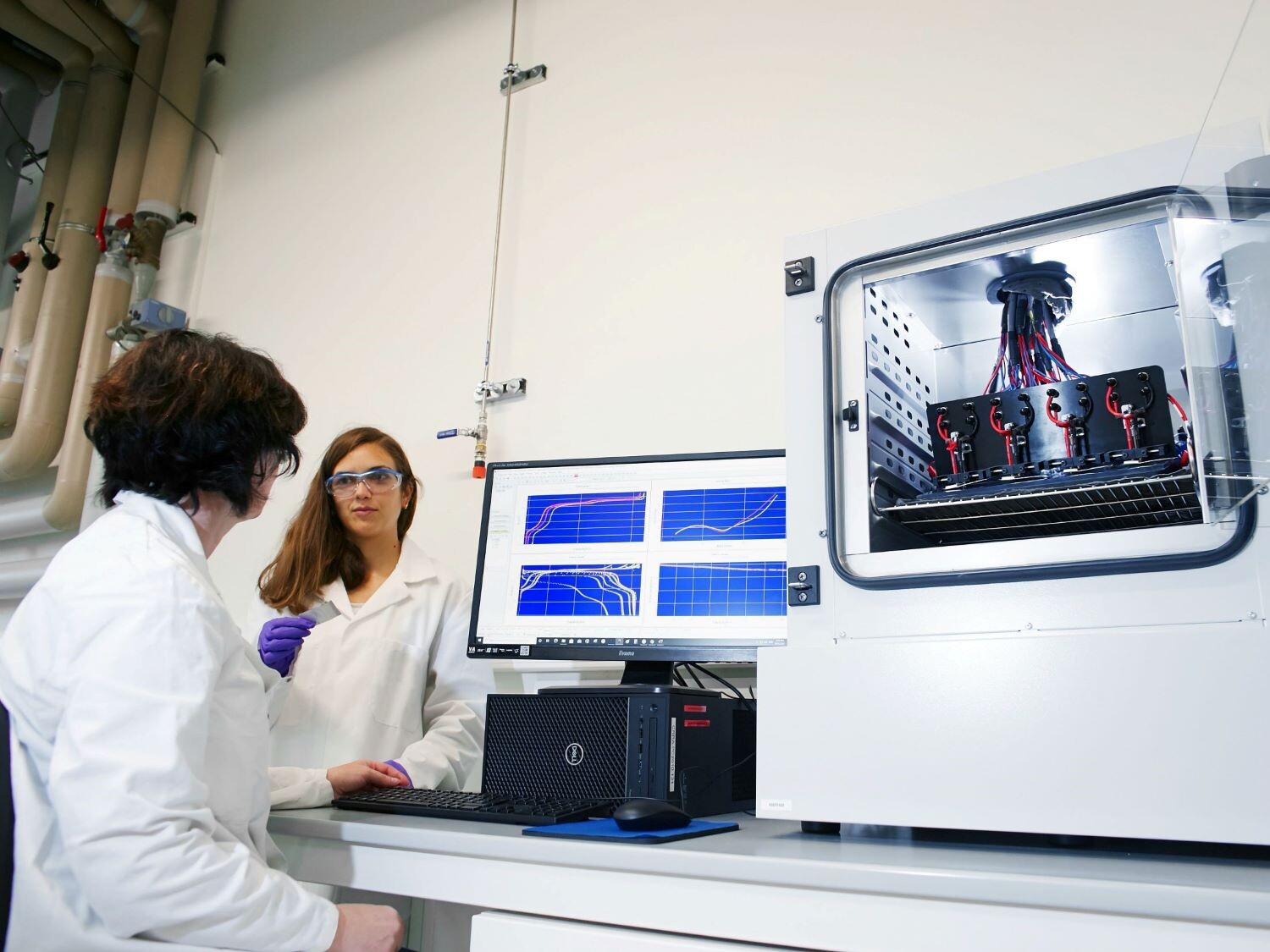

Leveraging its 17 R&D centers accross the world, Arkema develops new products, applications and production technologies to meet customers’ particularly demanding needs in cutting-edge sectors such as electric mobility, advanced electronics and renewable energies.

Anticipate future trends

Arkema anticipates technological and market changes and is developing today, through a dedicated incubator structure, the breakthrough innovations that will meet society’s needs in the years to come.

Arkema has thus developed Elium® resin, used notably to make recyclable wind turbine blades, as well as Piezotech® electroactive polymers, which are used in particular in the area of haptics for virtual reality and sensors for consumer electronics.

Contribute to our operational excellence

The Group's R&D provides innovations to production facilities enabling to produce safely and competitively while reducing as much as possible its environmental footprint.

Arkema group R&D key figures

In a world marked by the acceleration in sustainable development challenges and technological disruptions, Arkema focuses its research efforts on ensuring its solutions offering adequately addresses market needs and specific customer expectations worldwide.

Towards a portfolio of ever more sustainable solutions

The Group is actively assessing its portfolio of solutions in light of sustainability criteria.

At end-2024, 89% of sales had been assessed, of which 53% significantly contribute to the United Nations Sustainable Development Goals.

5 key high-growth markets

The Group has identified five key high-growth markets in which it holds leading-edge technologies which will allow to generate one quarter of Arkema's sales by 2028 and for which it assigns more than 50% of R&D spending:

- green energy and electric mobility;

- advanced electronics;

- sustainable lifestyle;

- efficient buildings and homes;

- water filtration, medical devices and crop nutrition.

Our 4 sustainable innovation transverse themes

In addition to the various R&D programs serving our five key markets, four transverse themes within the Group contribute to the decarbonization of its value chain and the development of more environmentally friendly solutions.

The R&D teams boast experts who carefully watch market trends, and relentlessly work at putting in place pioneering and sustainable solutions.

Go further:

The incubator: enhancing high-potential innovations

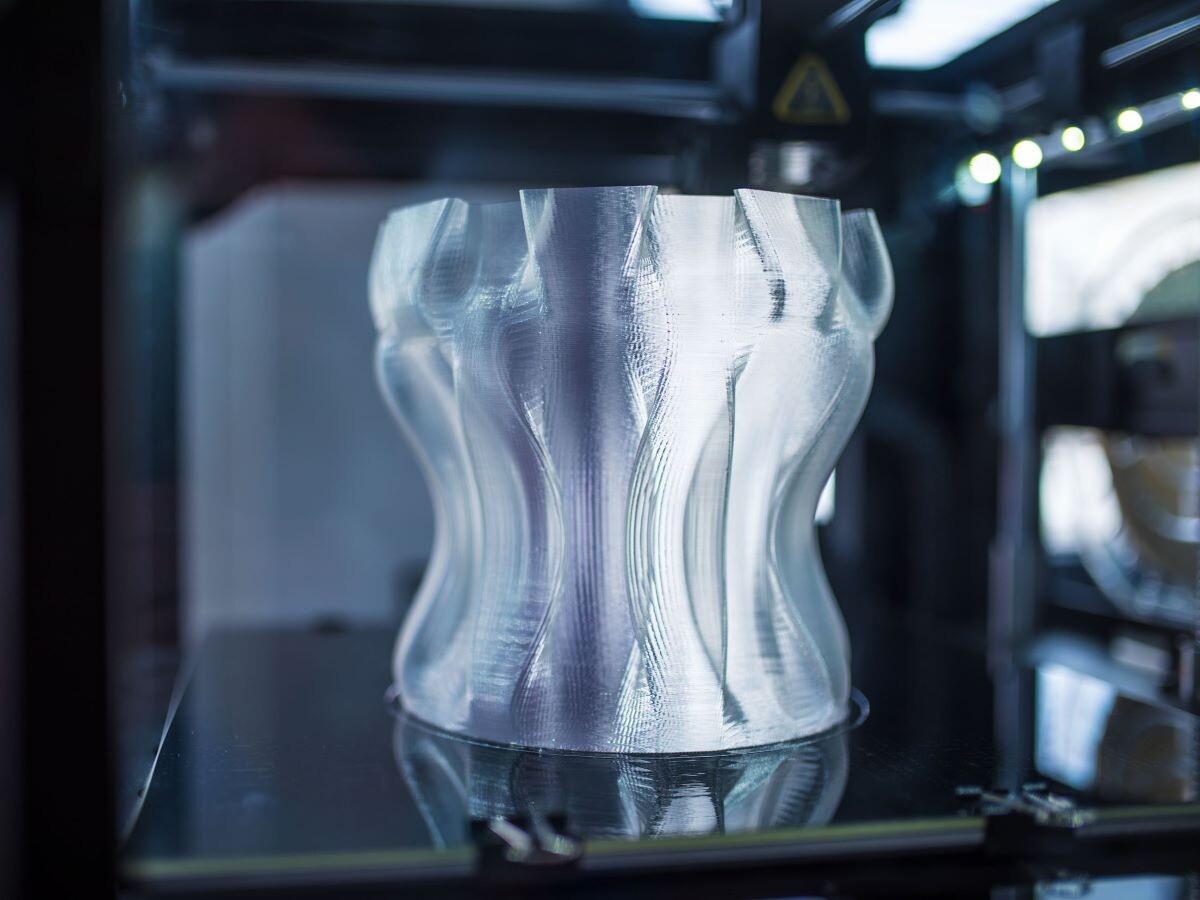

The role of the "incubator" is to identify products with a high potential and bring them to fruition. Within this original structure with its own technical and financial resources, researchers and scientific directors are charged with developing nanomaterials and new generation polymers.

Graphistrength® carbone nanotubes, Piezotech® electroactive fluoropolymers, or thermoplastic resin Elium® are amongst the innovations which prepare the future of the Group, and are poised to completely transform many application sectors.

INNOVATIVE WITH, our magazine “that connects the ideas of the future”

INNOVATIVE WITH is our magazine that sheds light on our unique R&D expertise in innovative materials and on our collaborations with the greatest experts - laboratories, SMEs, start-ups - in promising areas like new technologies and renewable energies.