Thermal management solutions

Automotive thermal management has two primary objectives:

- Maintain desired temperatures for efficient operation of the vehicle

- Provide an optimized temperature for passenger comfort in the cabin.

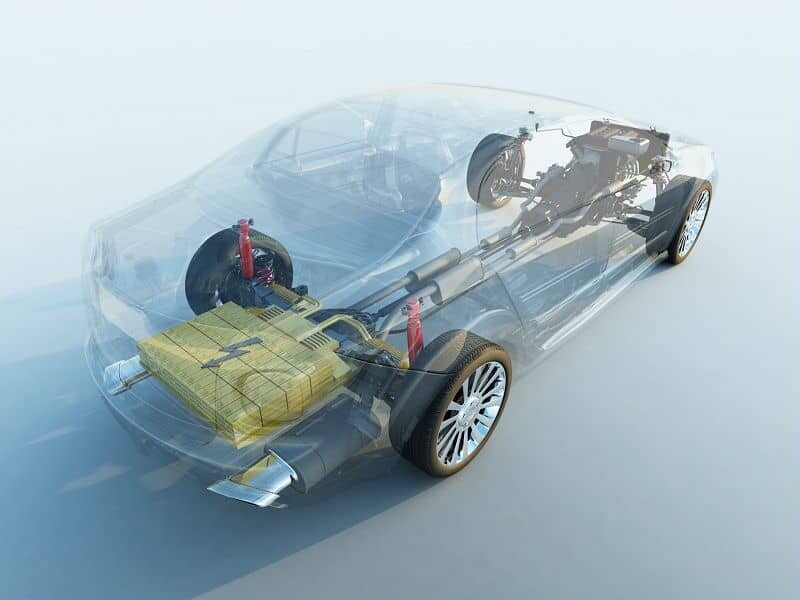

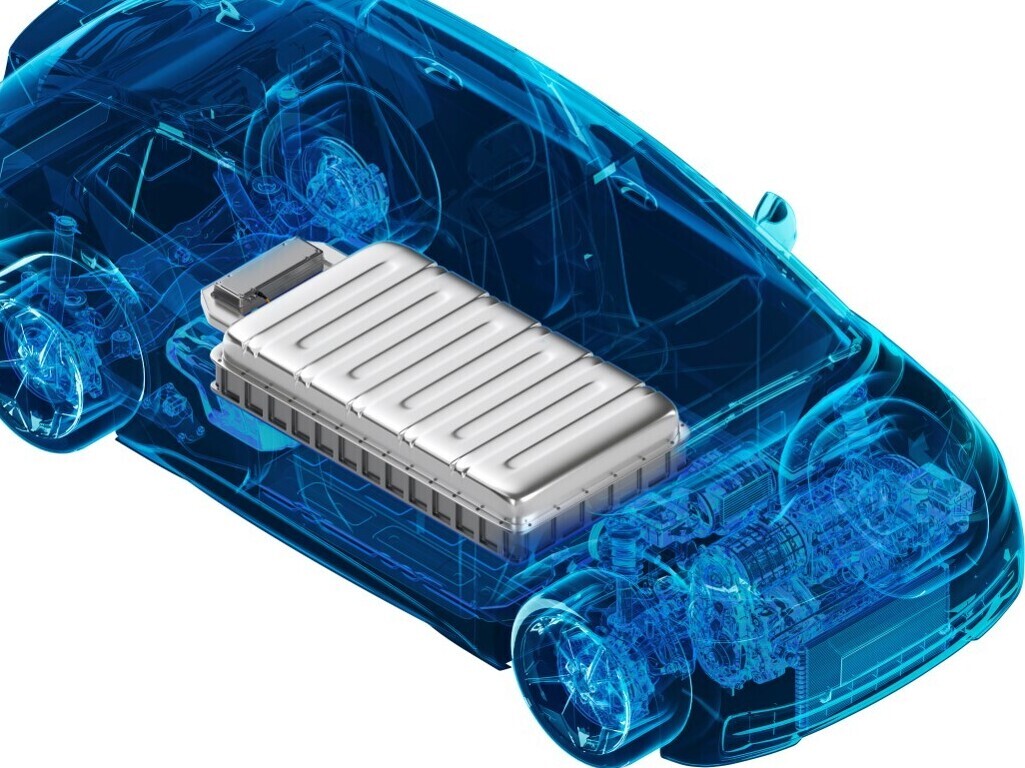

With the emergence of Battery Electric Vehicles (BEV) and Hybrid Electric Vehices (HEV), thermal management is going through drastic evolutions towards more complexity and system integration. In conventional thermal management, surplus heat from ICE is sufficient for cabin heating. Next generation BEV thermal management systems will require battery energy to provide cabin heating for passengers. Another key element of battery thermal management is the heat transfer from the module and battery pack outside of the battery system to ensure optimum temperature range for its operations. We have time-proven expertise in the thermal management built over the years of supplying the automotive industry. Our team offers technical know-how for optimized design of thermal management systems. We innovate to develop sustainable and durable materials to drive the transition to next generation vehicles. Our solutions help to improve the efficient thermal management as well as reduce energy consumption by using lightweight solutions.

Thermal management for Lithium ion batteries

Lithium ion batteries are considered to be the main energy storage technology today for the automotive industry. Meanwhile improved thermal management to ensure the longevity of the battery life remains one of the main questions in the development of next generation vehicles. Due to the current higher charge and discharge rates in the BEV and HEV vehicles, the battery generates increased levels of heat. Ensuring sufficient heat transfer from the battery to its surroundings to maintain safe temperature range is the key to battery lifespan. We engage in innovative R&D to advance in high performance solutions for the durable functioning of the batteries in all climate conditions, while optimizing charging rate and cost of production.

Cooling circuits

BEV and HEV vehicles contain complex interconnected cooling systems. Our high performance polymers are ideals for cooling circuits due to their excellent mechanical strength, high flexibility and ease of processing. High performance long chain polyamides such as Rilsan® PA11 and Rilsamid® PA12 are the materials of choice for cooling circuits for their resistance to cooling media as well as road salt damage. Rilsan® PA11 is a lightweight and bio-based material made from sustainable castor plants suitable for extreme condition applications in the automotive industry.

Thermal conductive adhesives and gap fillers

To ensure efficiency and durability of lithium ion batteries, it is critical to maintain optimized temperatures between 15°C and 35°C. Thermal interphase materials (TIM) such as thermal conductive adhesives and gap fillers play a key role in the heat transfer in the battery system to guarantee reliable and long-term battery operation.

Bostik smart adhesives and sealants provide high performance solutions designed to address multiple needs of battery application: lightweight, ease of assembly and thermal management properties.

Immersion cooling solutions

Arkema continuously innovates and develops new solutions for next generation electric and hybrid vehicle batteries.

Our latest development is Low Global Warming Potential (GWP) immersion cooling solutions that contribute to improve fast charging and durability of the battery lifespan. Battery Solutions by Arkema is ready to assist our clients to co-develop and optimize cooling systems to ensure improved battery efficiency during vehicle operation and meet the growing demand of decreased charging time.

Sustainable Oleris® n-heptanoic acid used in the synthesis of high performance fluids with improved low viscosity at extreme low temperatures.

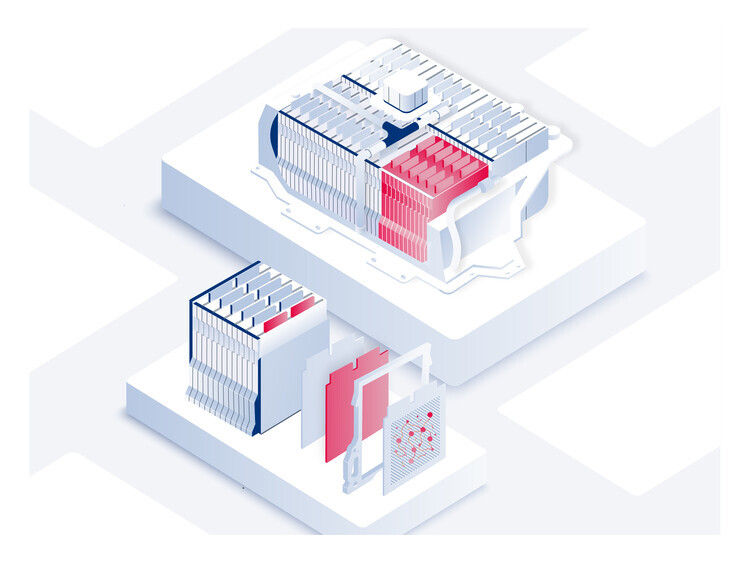

Inter-cell cooling

Battery thermal management is a complex system implemented at all levels of the battery system including cells. Efficient insulation for the battery cell contributes to optimized temperature maintenance for durable and healthy battery operation.

Automotive Solutions by Arkema presents sustainable materials for high performance applications such as inter-cell cooling. Bio-based Rilsan® Fine Powders are made of sustainable castor plants and are known for their extreme performance. Rilsan® Fine Powders key coating-specific properties are: excellent adhesion on metal substrates, high flexibility, and excellent insulation properties in low thickness coating applications (< 200 µm).

Air conditioning system in cabin

Air conditioning in the cabin is one of the key elements of passenger comfort. Evolving environmental regulations in the automotive industry requires an innovative approach with improved performance materials and technical expertise.

Our offer of solutions for air conditioning systems is not limited to only product supply. Our team of experts is ready to provide technical and regulatory assistance in any region across the globe.

Air conditioning circuit

Air conditioning circuit lines have highly demanding material performance specifications in terms of permeability, chemical resistance and high-pressure resistance. Orgalloy® polyamide alloys are a market leading solution that help to replace metal-rubber lines with a high performance plastics composition. Orgalloy® polyamide alloys provide excellent performance thanks to their key properties: high processability, good rubber adhesion, low permeability and excellent chemical resistance.

Refrigerant fluids

Refrigerants in the automotive industry is one of the most regulated elements due to its impact on the environment and global warming. Our experts in the refrigerants market are ready to help our clients to stay ahead of the trends and develop air conditioning solutions suitable for next generation vehicles while addressing consumer requirements for more sustainability. Forane® refrigerants range of products provides non-ozone depleting refrigerant solutions for improved passenger comfort.